- Easy operation with Windows 7 system in Chinese and English language,

very convenient to use - 2 sets the high-resolution camera for accurate vision alignment correction

- a precision electric feeder with double motors

SMT mounter for LED DOB bulb

Description

SMT mounter for LED DOB bulb

Product description

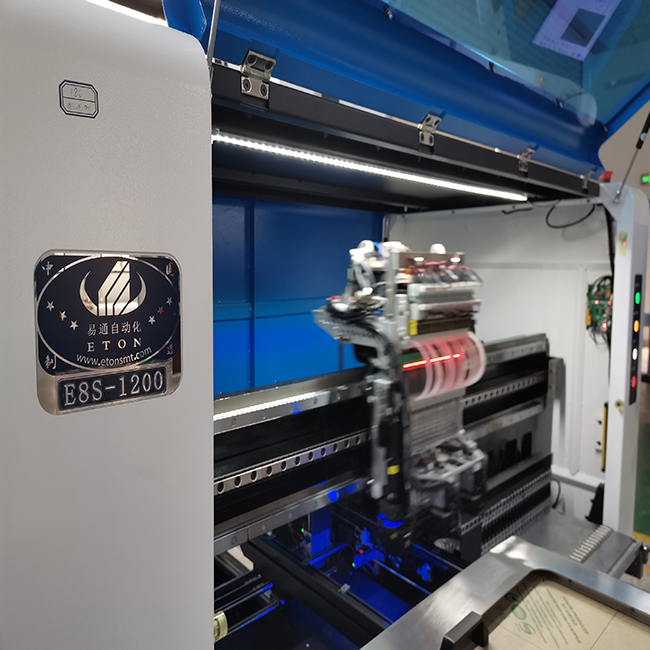

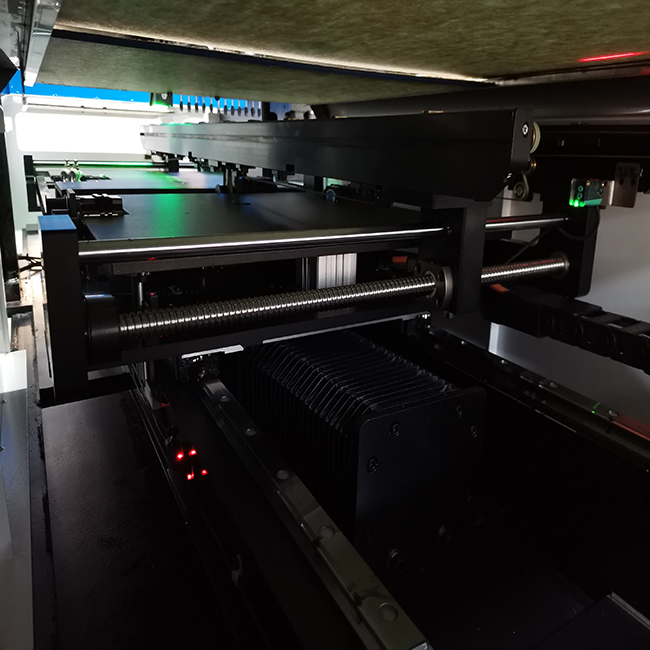

E8S-1200 model, SMT pick and place machine

- The most ideal production capacity is 45000CPH, an economical placement machine with fast production capacity.

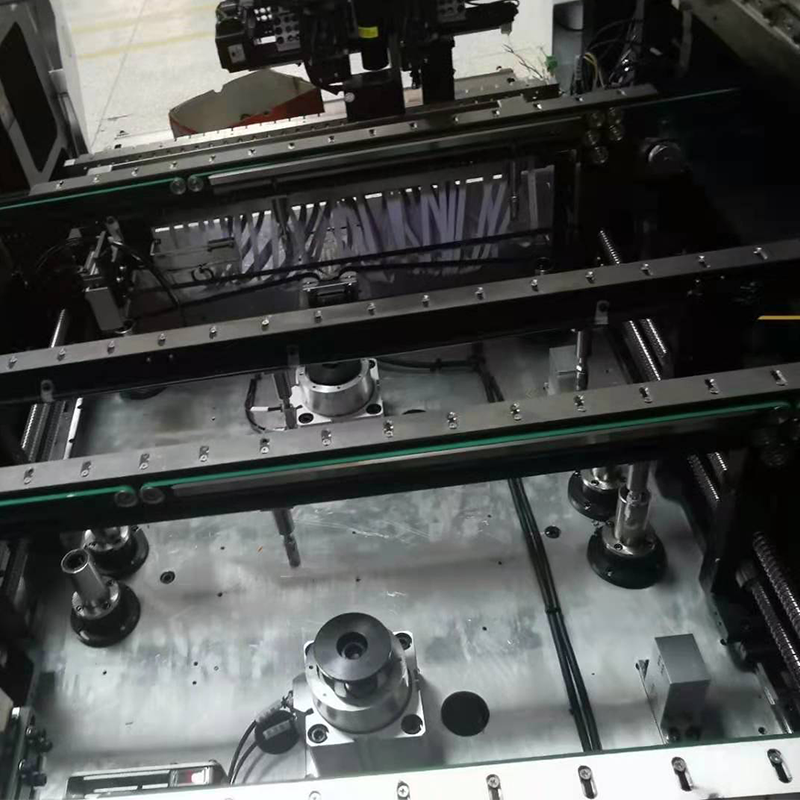

- 12 nozzles, 28 feeder seats, each nozzle is independent, controlled by an independent servo motor, with very high precision, can rotate at any angle, and mount different PCB boards

- The high-end magnetic levitation linear motor is used after the working area of the head. The use of the linear motor greatly improves the accuracy, stability and service life of the equipment.

SMT mounter for LED DOB bulb

Parameter

|

PCB Length Width |

Max:1200*500mm Min:100*100mm |

|

PCB Thickness |

0.5-5mm |

|

PCB Clamping |

Adjustable pressure pneumatic |

|

Mounting Mode |

Group picking and separate placing\separate picking and separate placing |

|

Mounting Precision |

±0.04mm |

|

Mounting Height |

<15mm (Automatic Changing) |

|

Mounting Speed |

45000 CPH |

|

Components Space |

0.2mm |

Five test methods of PCBA

PCBA process is complex. In the production and processing process, various problems may occur due to improper equipment or operation, which can not guarantee that the products produced are qualified. Therefore, PCBA test is required to ensure that each product will not have quality problems.

PCBA test mainly includes five forms: ICT test, FCT test, aging test, fatigue test and test in harsh environment.

- ICT test: including on-off, voltage and current values, fluctuation curve, amplitude, noise, etc.

- FCT test: it is necessary to burn ic program, simulate the function of the whole PCBA board, find problems in hardware and software, and equip necessary production fixtures and test racks. This test requires the functional description provided by the customer and the support of the customer tester to complete this test

- Fatigue test: sample the PCBA board, operate the function at high frequency and for a long time, observe whether there is failure, and judge the probability of failure in the test, so as to feed back the working performance of Printed Circuits Board in electronic products.

- Testing in harsh environment: the PCBA board is exposed to the temperature, humidity, drop, splash and vibration of the limit value to obtain the test results of random samples, so as to infer the reliability of the whole batch of PCBA board products.

- Aging test: power on PCBA board and electronic products for a long time, keep them working, and observe whether there are any failure faults. Electronic products after aging test can be sold in batches.

FAQ

Q: Is hard to use these machines?

A: No, not at all. All our machine are automatic, you just type in the program and it will work. The operation is relatively simple and I believed that certainly learn in two days.

Q: if there is a problem with the machine,can it be repaired?

Of course, the machine failure rate is 0.001 , and in addition to the warranty period, we also provide you with free maintenance 1-2 times a year.

Q: Is the machine free of charge?

A: Yes. Our warranty for the whole machine is one year, but in addition, we provide customers with free maintenance once or twice a year.

Contact us:

David Whatsapp/Wechat/Tel: +86 13827425982

E-mail:david@eton-mounter.com