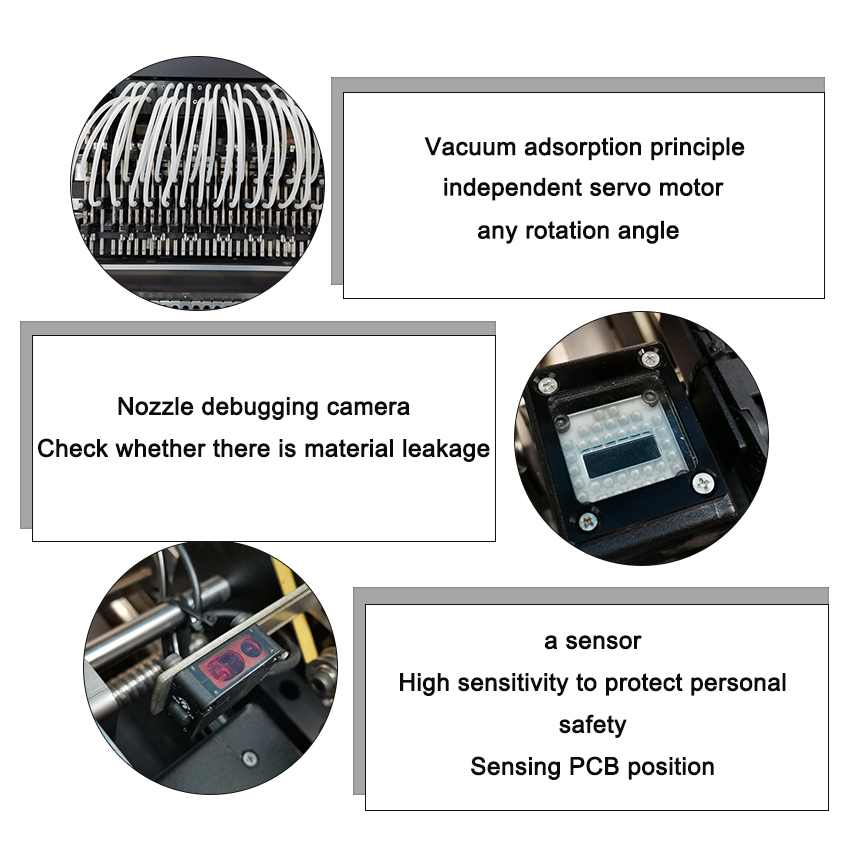

- High capacity, can produce four kinds of raw materials at the same time

- Easy operation with Windows 7 system in Chinese and English language,

very convenient to use - 5 sets the high-resolution camera for accurate vision alignment correction

- a precision electric feeder with double motors

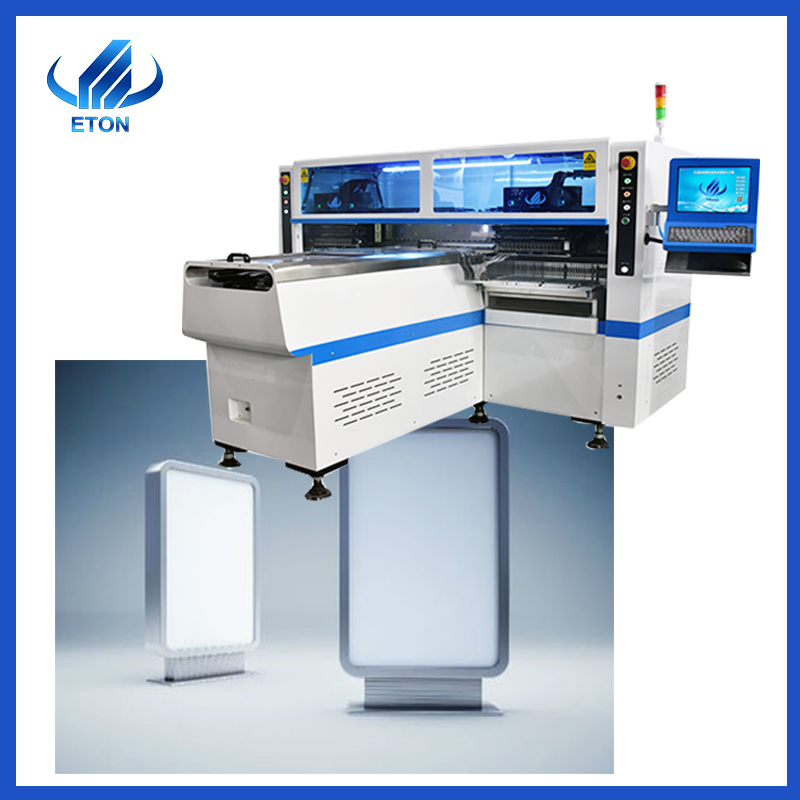

SMT pick and place machine with LED panel lights

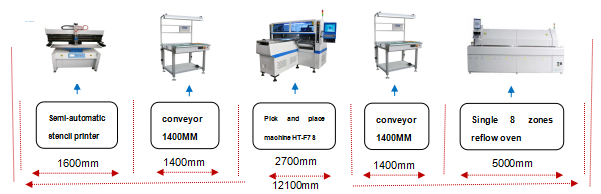

Description

|

Model |

F9 |

|

PCB Length Width |

Max:1200*330mm Min:100*100mm |

|

PCB Thickness |

0.5-5mm |

|

PCB Clamping |

Adjustable pressure pneumatic |

|

Mounting Mode |

Group to take and group to mount |

|

Repeat Mounting Precision |

±0.02mm (Repeat precision) |

|

Mounting Height |

≦5mm |

|

Mounting Speed |

200000~250000 CPH |

|

Components |

LED 3014/ 3020/ 3528/ 5050 and capacitors, resistors, bridge rectifiers, etc. |

SMT pick and place machine with LED panel lights

Product descrtion

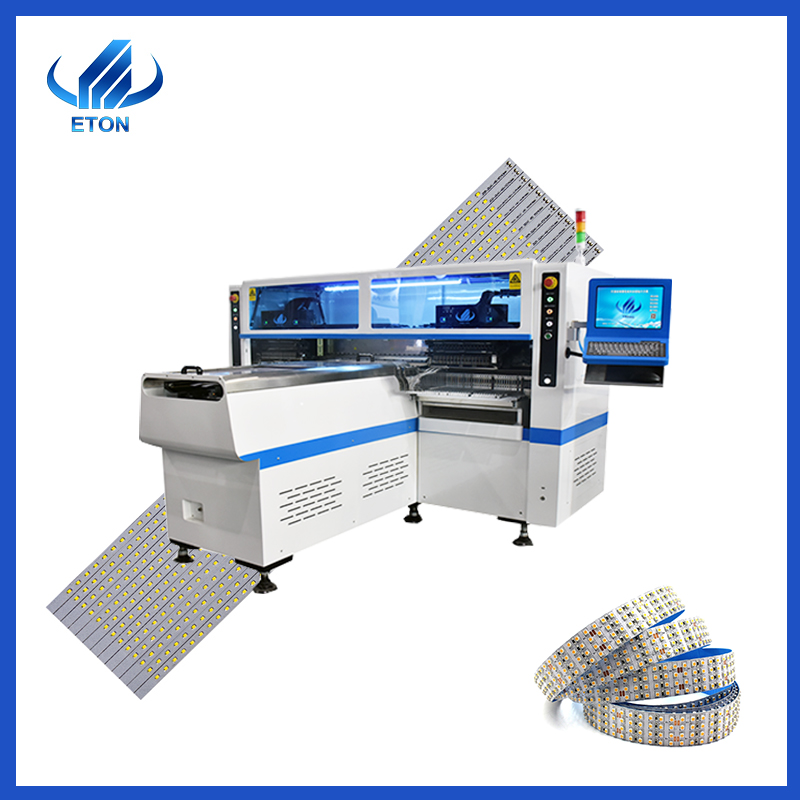

F9 model, SMT high-speed placement machine

- Exclusive patented technology, group picking and group sticking, saving the time of suction nozzles picking up materials

- 68 nozzles, 68 feeders, four different materials can be patched at the same time

- The ideal production capacity is 250000CPH

- Minimum patch element 0603, maximum element height 5mm

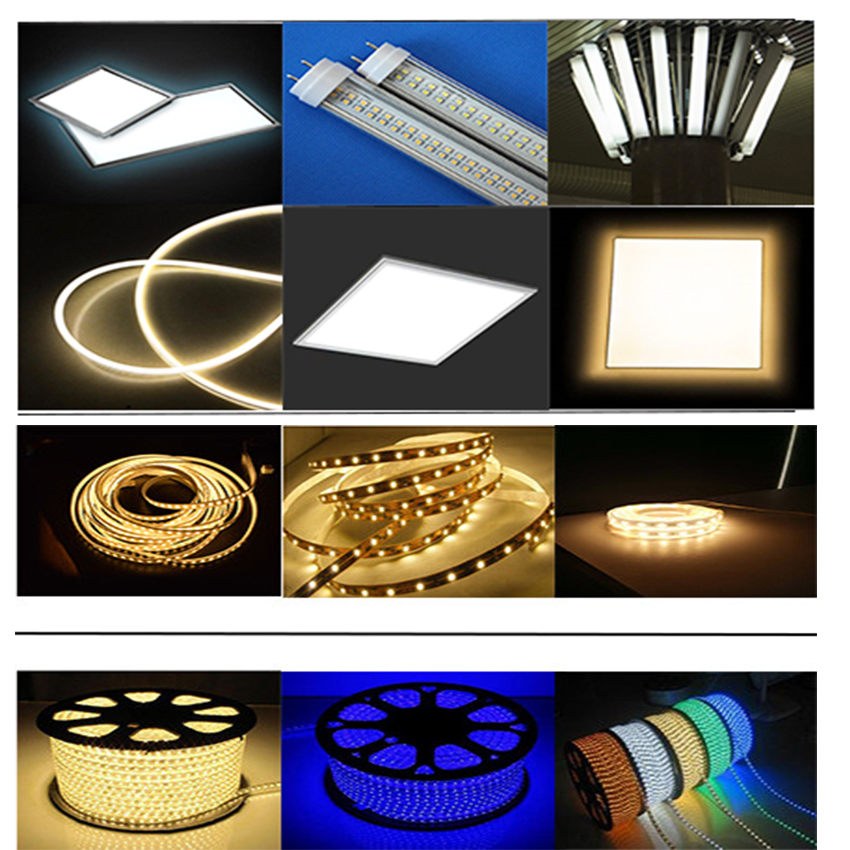

- Suitable for linear LED lamp products, such as lamp tubes, lamp strips, panel lamps, outdoor display screens, etc.

- The optimal capacity exceeded 250000cph

What are the reasons that affect the quality of SMT solder paste printing

Solder paste printing is the first process of SMT. If it is not handled properly, other subsequent links will be affected. SMT is an important link in PCB production. So, what affects the printing quality of solder paste?

- Solder paste

Solder paste is a slurry made by mixing alloy powder and flux. Whether the components can be well soldered to the pad depends on the quality of the solder paste. The main factors affecting the viscosity of solder paste are: alloy powder quantity, particle size, temperature, blade pressure, shear rate, flux activity, etc. If the quality of the solder paste is not up to standard, the soldering cannot be achieved well, and the natural printing effect is not ideal.

- Storage

The storage of solder paste is also very important. If the solder paste needs to be recycled, attention must be paid to issues such as temperature and humidity, otherwise the quality of the solder joints will be affected. Too high temperature will reduce the viscosity of solder paste, and too high humidity will lead to deterioration. In addition, recycled solder paste and new solder paste should be stored separately and used separately.

- Steel mesh template

Stencils are the pads needed to apply solder paste to the PCB board. The quality of the stencil directly affects the printing quality of the solder paste. Before processing, the thickness and opening size of the stencil must be confirmed to ensure the printing quality of the solder paste.

- Printing equipment

A printer is a device that prints solder paste onto a PCB model. It is the equipment that has the greatest impact on craftsmanship and quality. Printing machines are mainly divided into manual printing machines, semi-automatic printing machines and fully automatic printing machines. These presses have different features and functions. According to different needs, use different printing machines to achieve the best quality.

- Printing method

Solder paste printing methods can be divided into contact printing and non-contact printing. The gap between the screen and the printing plate is called non-contact printing.

- Printing speed

A fast squeegee speed is beneficial to the rebound of the stencil, but it also hinders the transfer of solder paste to the pads of the printed board, while too slow speed will result in poor resolution of the solder paste printed on the pads. On the other hand, the speed of the squeegee has a lot to do with the viscosity of the solder paste. The slower the squeegee, the more viscous the solder paste; the faster the squeegee, the less viscous the solder paste.