Description

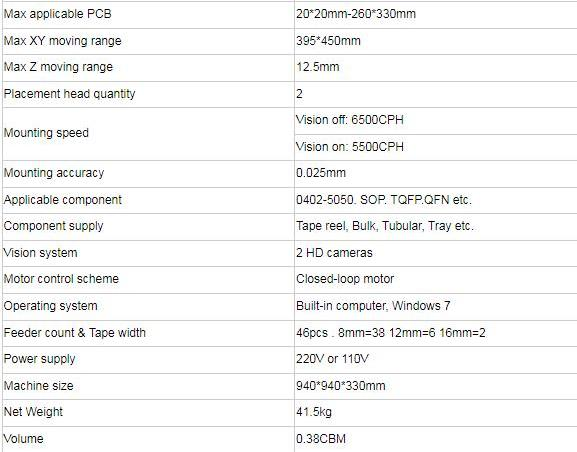

Machine main parameter

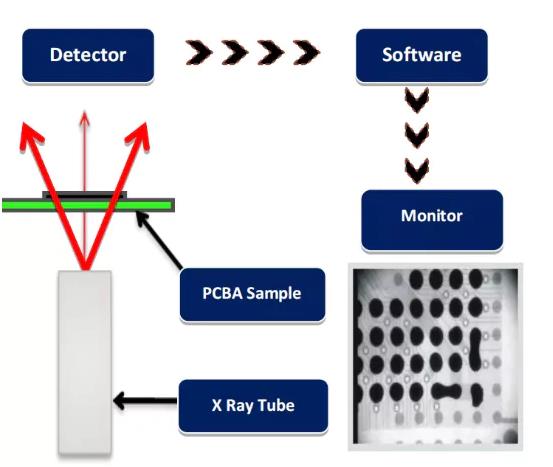

X-ray inspection is a non-destructive inspection

which is mainly used to inspect the solder joints at the bottom of the equipment that cannot be inspected by naked eye or AOI, such as BGA, CSP, flip chip, QFN, double row QFN, DFN and other solder joints, as well as the internal damage of printed circuit boards, component packages, connectors and solder joints. The computer further analyzes or observes that the opacity coefficients of various materials to X-rays are different. The processed gray-scale image can display the difference of object density or the thickness of the inspected material.

Maintenance period 1 year

One year warranty, during warranty, any parts that need to be repaired and replaced will be free.

Software and hardware lifetime maintenance

Free upgrade software, the software is Reach and developed by ETON, so we support whole lifetime free upgrade updates.

Visit customers regularly and gather information

Visit clients regularly. We attend the different exhibitions in different cities every year, at the same time, we will visit local clients and support our service and collect feedback on customer suggestions in time.

Provide the latest information about technology and equipment

We give professional technology suggestions to our clients. And share the updated news with our clients.