- The correction method adopts the movement of the net support arm to coordinate the X, Y, Z correction adjustment of the printed matter (platen), and the correction is convenient and simple.

- Using microcomputer PLC control,Human-machine interface touch control, Single/double printing and manual/semi-automatic modes can be selected.

- The squeegee seat can be adjusted back and forth, and the printing squeegee can be adjusted by ±15° according to the needs of product printing.

- Using air cylinder and magnetic proximity switch, the worktable reciprocates, the accuracy of the printing surface can reach ±0.01mm.

- Use air pressure 4-6kgf/cm², printing table area 320*500mm and printing accuracy ±0.02mm, machine repeat accuracy ±0.02mm.

- With automatic counting function and alarm times setting, convenient for output statistics.

- With the adjustment of the stopping time of the printing action, it is convenient to meet the production needs.

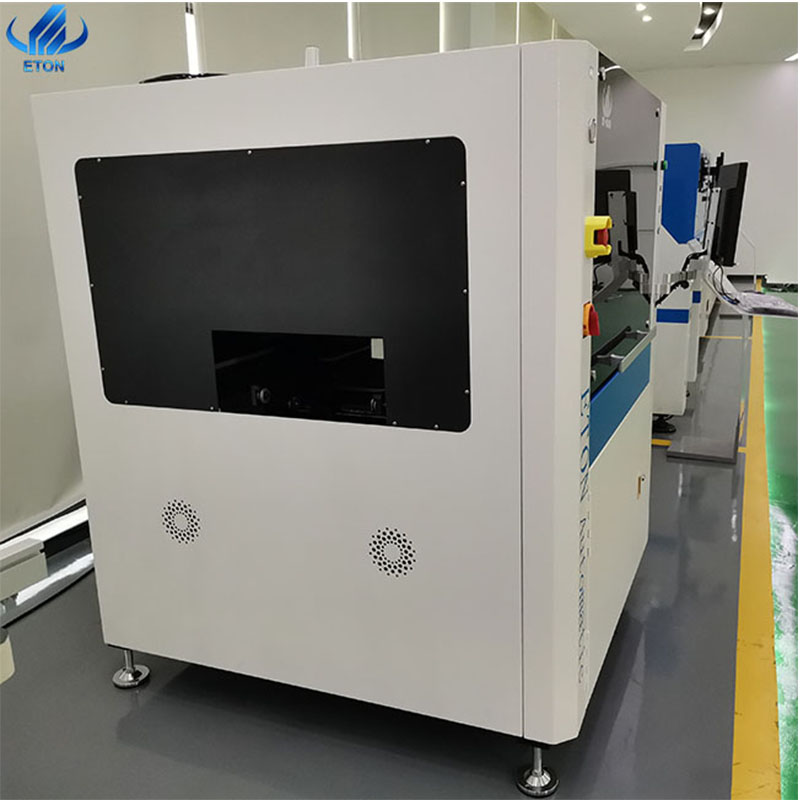

Solder-paste screen stencil printer for PCB

Description

Features of Solder-paste screen stencil printer for PCB

- Adopt high-precision linear guide and ultra-quiet motor,Squeegee printing is more stable.

- Use imported electrical raw materials,Stable and reliable performance.

- Suspended scraper design can automatically adapt to uneven surfaces.

- Input total power supply voltage: single-phase 220V 50/60Hz, total power 100W.

- The printing base can be lifted up by 45° and can be fixed, which is convenient for the loading and unloading of the scraper and the cleaning of the stencil.

- The Printing Block can be moved forward and fixed, which is convenient to match the position of the stencil mesh pattern to obtain better printing results.

- The mesh support arm can be adjusted left and right separately, suitable for 550~650mm stencil.

- The combined printing platen is equipped with a fixed slot and a positioning PIN, which is quick to change and easy to locate, and is suitable for single-sided substrate and double-sided substrate operations.

Specifications of Solder-paste screen stencil printer for PCB

|

Model |

ET-S600 |

|

Dimensions |

1400*800*1680mm |

|

Platform size |

650×320mm |

|

PCB size |

600×300mm |

|

Template size |

550×830mm |

|

Printing speed |

0-8000mm/min |

|

PCB thickness |

0-50mm |

|

PCB fine tuning range |

Front/side±10mm |

|

Power supply |

1PAC 220V 50/60HZ |

|

Platform height |

850±20mm |

|

Repeatability precision |

±0.01mm |

|

Positioning mode |

Outside/Reference hole |

|

Weight |

Approx.200Kg |

ETON Advantages

Efficient team: The best suggestions of full SMT lineequipment according to your budget and site.

Competitive price: We are directly manufacture of theETON pick and place machine, so we can give you thebest competitive price with high quality materials.

High quality: We have strictly quality control during allproduction from raw materials to the finished machine.

High efficiency: Allmachines parts are made byourselves, so it” s convenient to control the timeschedule and quality timely.

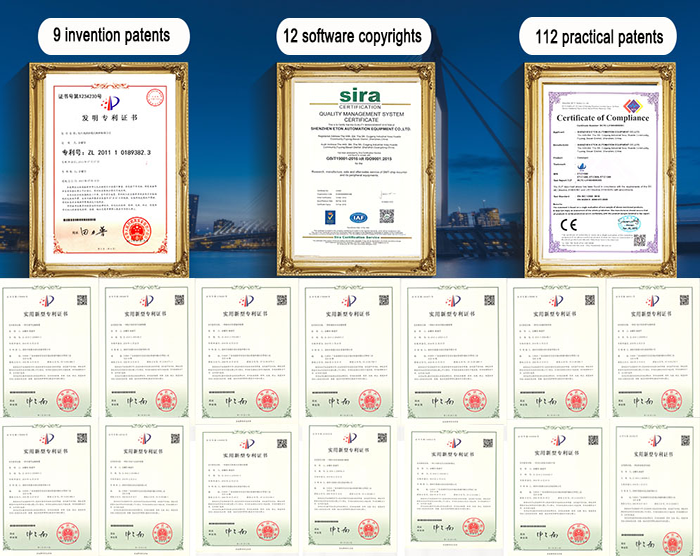

Certificates

Our company has obtained 9 invention patents, 12 software Copyrights and 112 practical patents

Patent number: ZL 2011 2 0237740.9\ ZL 20 11 2 0334606.0\

ZL 2012 2 0178869.1\ ZL 2012 2 0415505.0\

ZL 2012 2 0415044.7\ ZL 2012 2 0415356.8\

ZL 2012 2 0415061.0

FAQ

Q: How can I get to know you better?

A: You can have a specific understanding of our company through our company’s official website. After the epidemic, you can come to our company to know offline under safe conditions. Off-line can make you have a deeper impression on our company.

Q: Are you a trade company or a manufacturer?

A:We are an experienced manufacturer of SMT. Our company has been established for ten years, the company has more than 300 employees, the company is a large-scale, is the top domestic enterprises

Q: What’s your operating system?

A: Our operating system is windows 7.

Q: If I have any questions that I don’t understand, can I ask you at any time?

A: Yes. If you have any questions, please don’t hesitate to ask me.