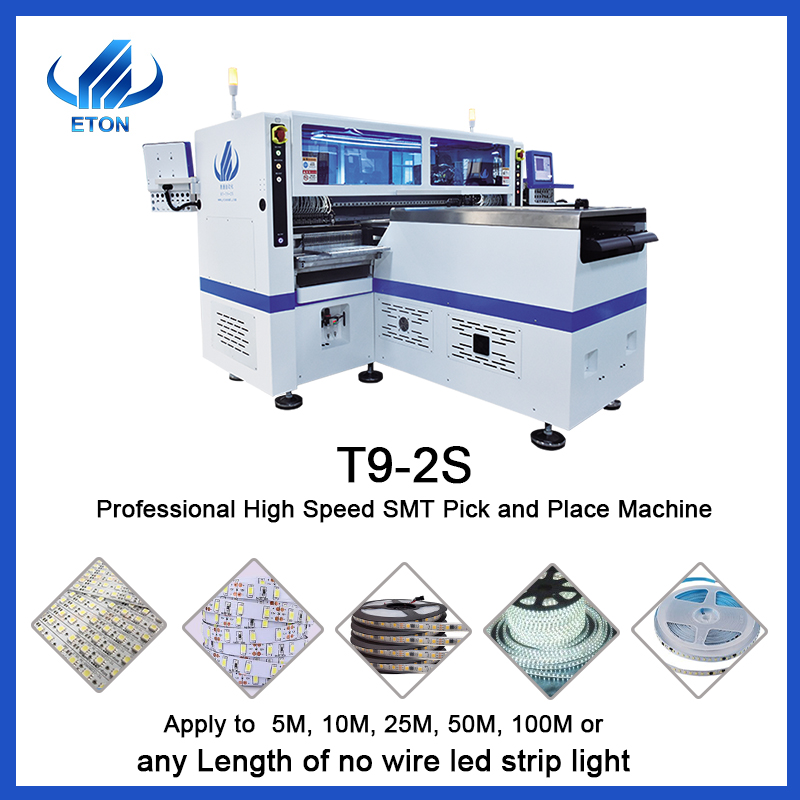

Ultra mounting speed: optimum capacity reach 500000CPH.

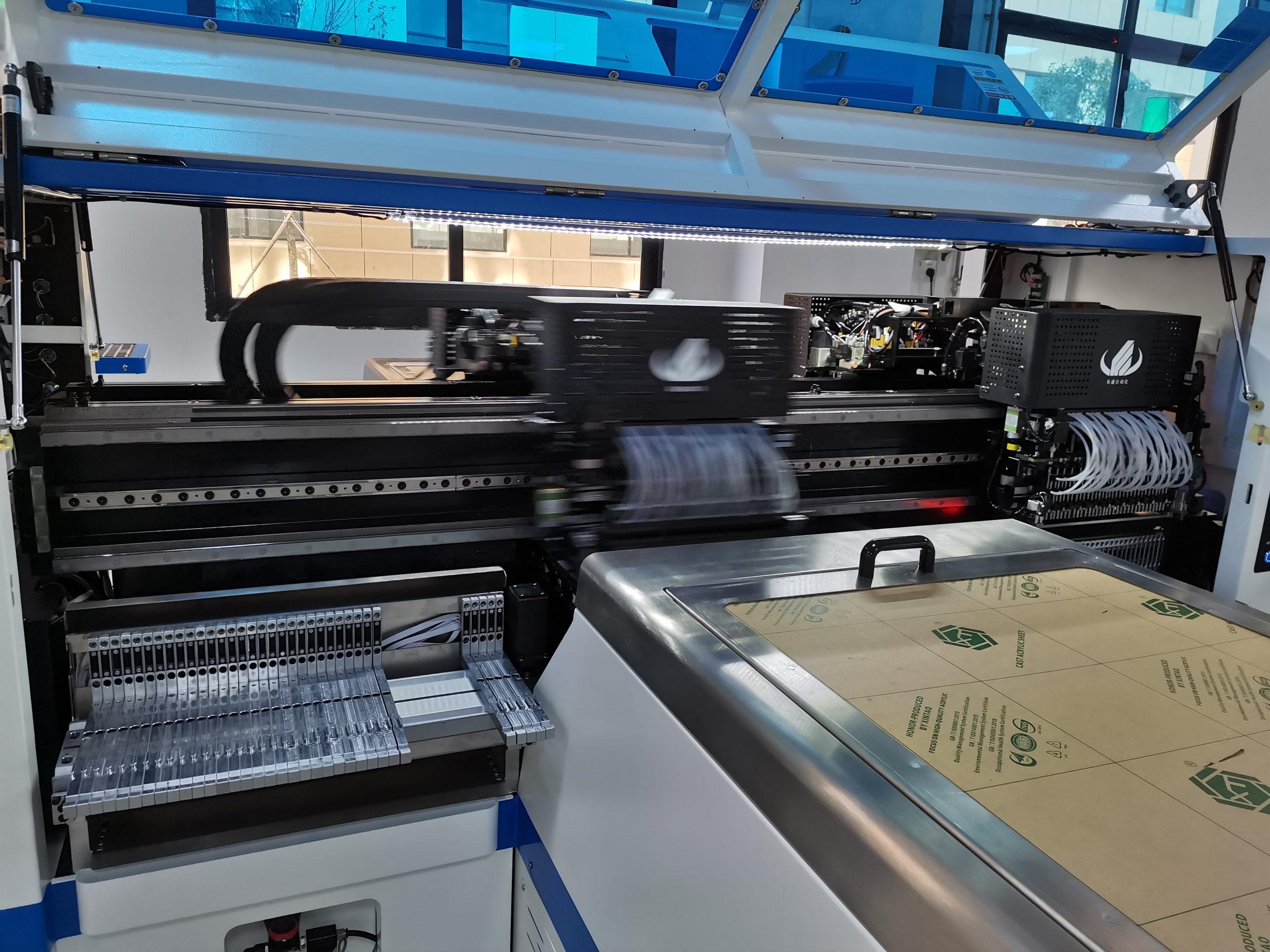

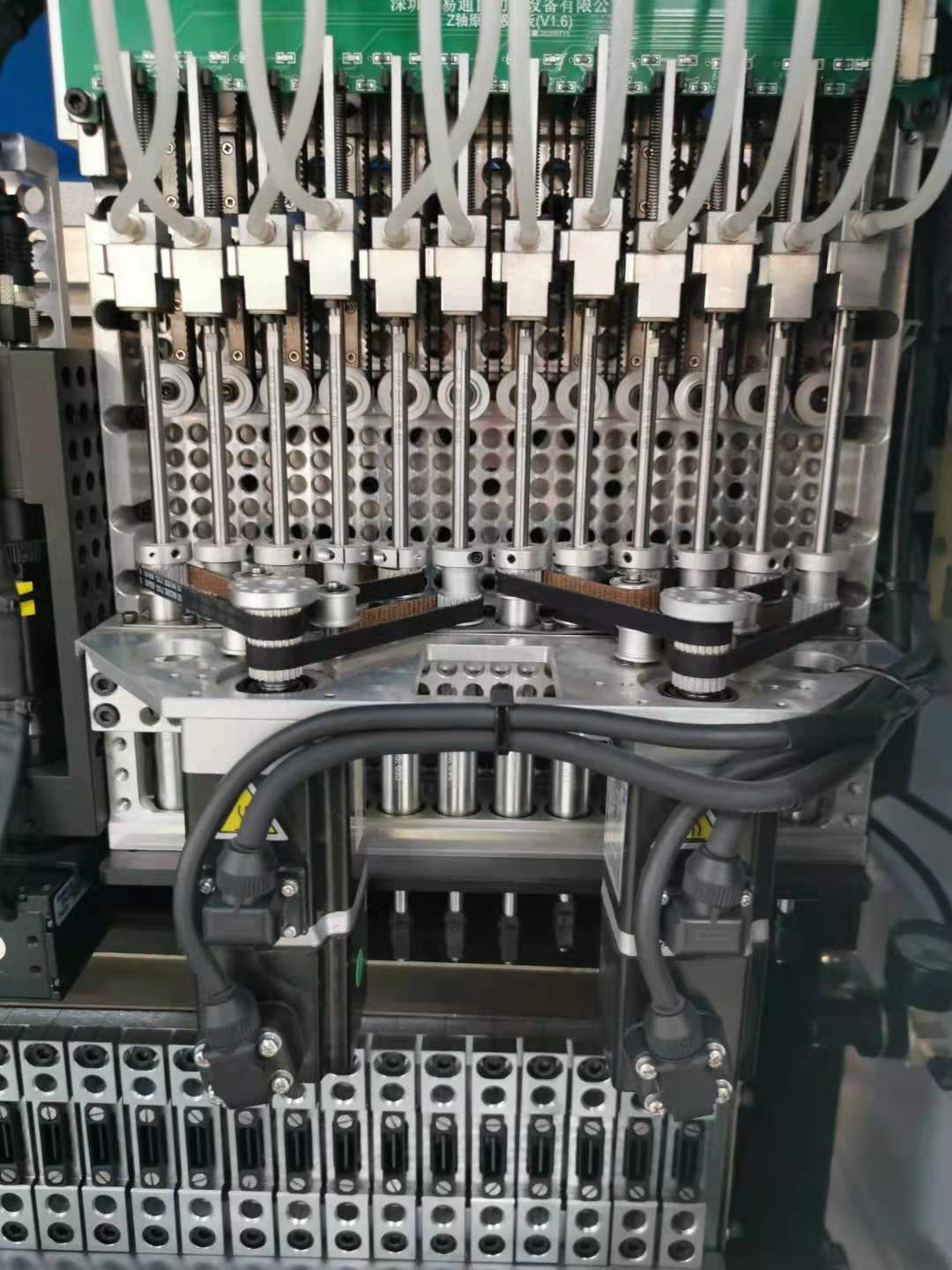

Mounting head: 4 mounting heads, each mounting head has 34 PCS heads, total has 136 PCS heads

Feeder station: total has 136 PCS heads

Mounting mode: realize the function of two time picking and once placing; produce four kinds of materials at the same time;