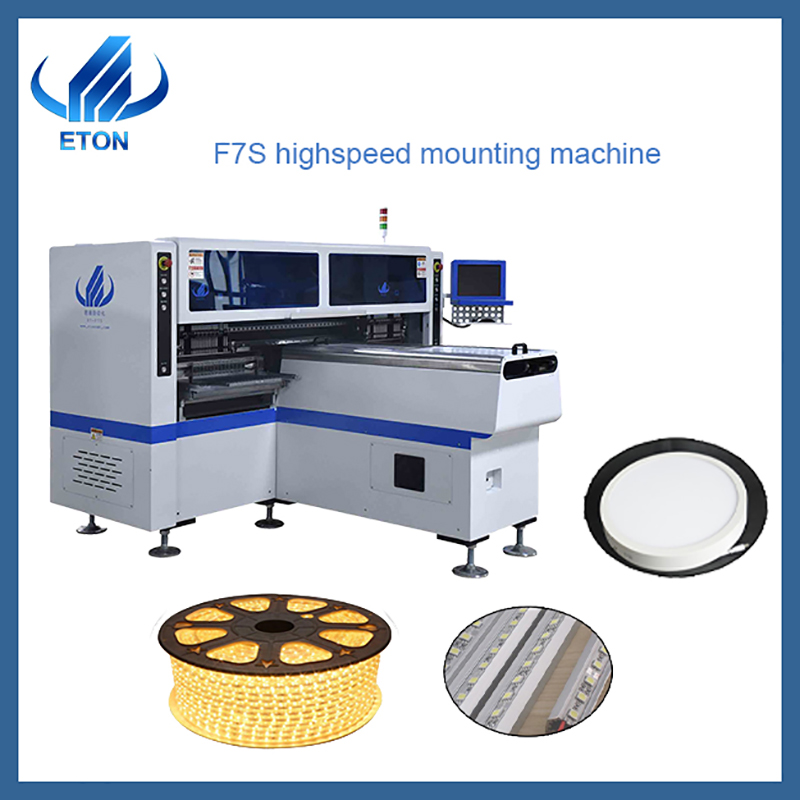

E8D is a dual-mode multi-function machine. Each module has a set of programs to control independently.

-

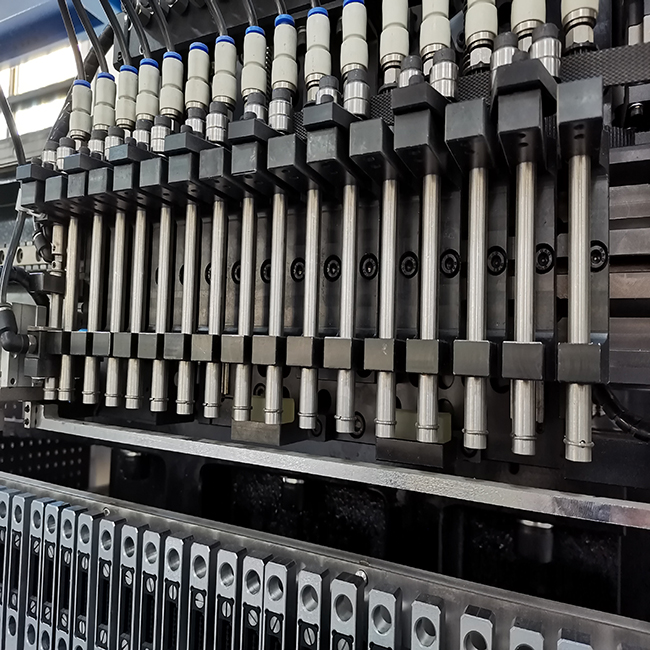

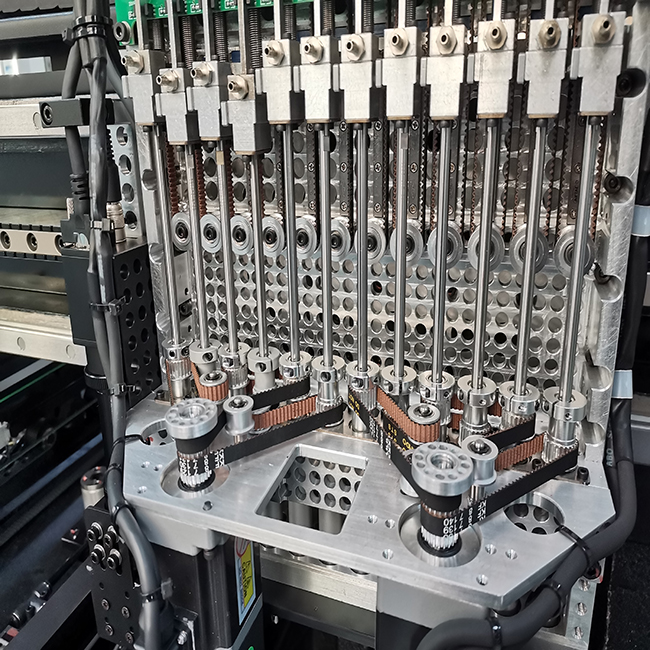

24 pcs mounting head(support customized)

-

Max PCB Szie :1200*300mm(support customized)

-

Double module arms,can produce different products

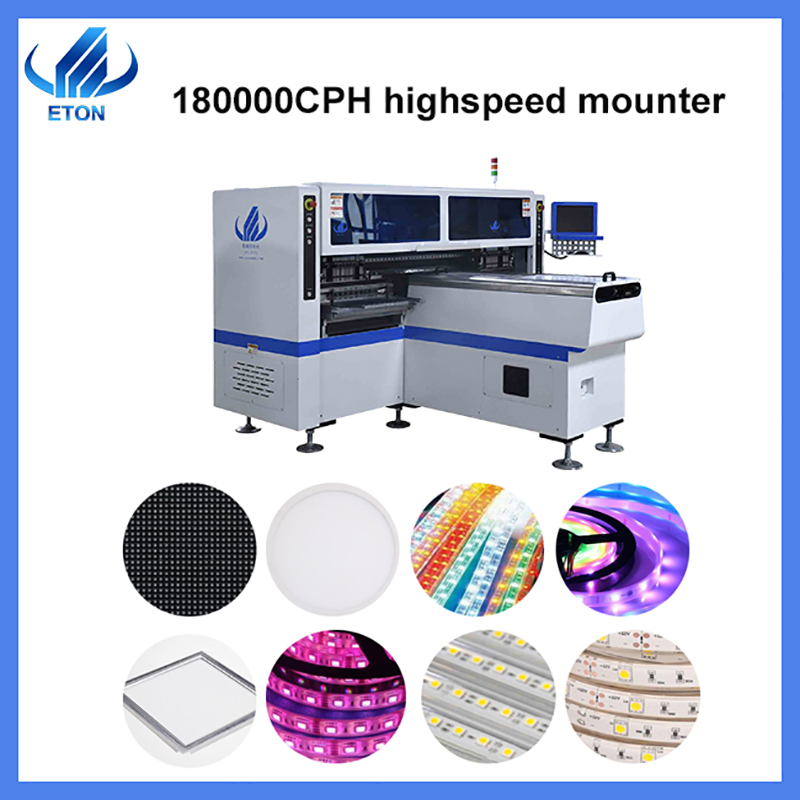

- E8D is a high-speed multifunctional Mounter with improved speed.

With the increase of modules, the production capacity is twice that of E8S.

The optimal capacity is 90000CPH