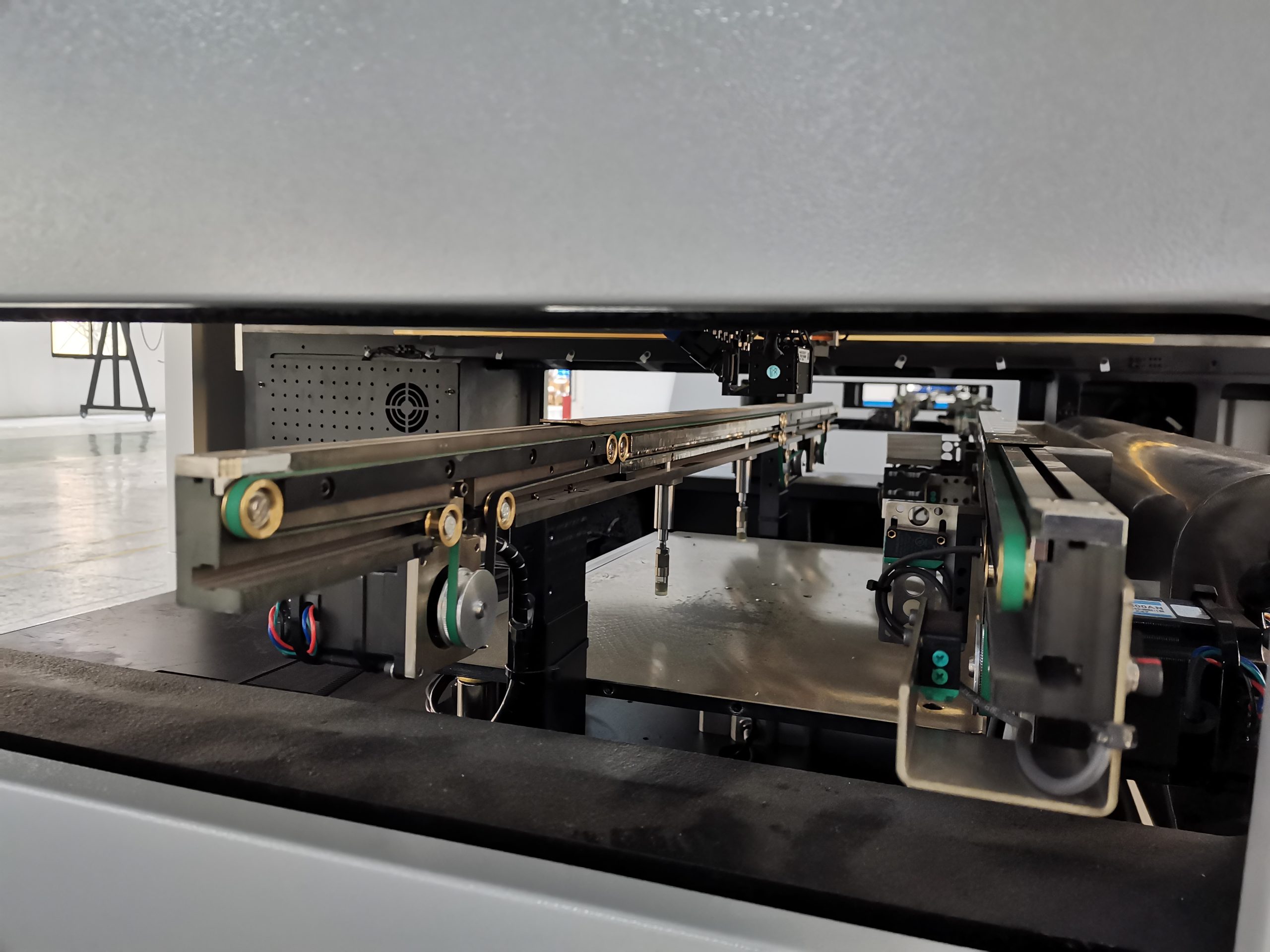

- Independent two operation systems, 2 computers, and two modules, so you can

produce 2 different products at the same time - There is 4 high-end magnetic linear motor for each module, more smooth and

faster than servo motor - Two electronic conveyors for each module

- Easy operation with Windows 7 system in Chinese and English language,

very convenient to use - 4 sets the high-resolution camera for accurate vision alignment correction

- a precision electric feeder with double motors

-

-

1. The PCB size of HT-E8D which can mount is 100*100mm-1200*300mm

2. DOB bulbs light SMT assembly machine HT-E8D can produce 2 different applications at the same time in double module

3. HT-E8D has 24 heads and 48 feeders station with double mounting heads,one mounting head has 12 heads, each head is controlled independently by one servo motor

-

The PCB size: max 500*350mm min50*50mm

The optimal capacity can reach 40000CPH

Apply to 0201~40*40mm packages and IC etc.

Non replace modular head

-

The PCB size: max 500*350mm min50*50mm

The optimal capacity can reach 40000CPH

Apply to 0201~40*40mm packages and IC etc.

Non replace modular head

-

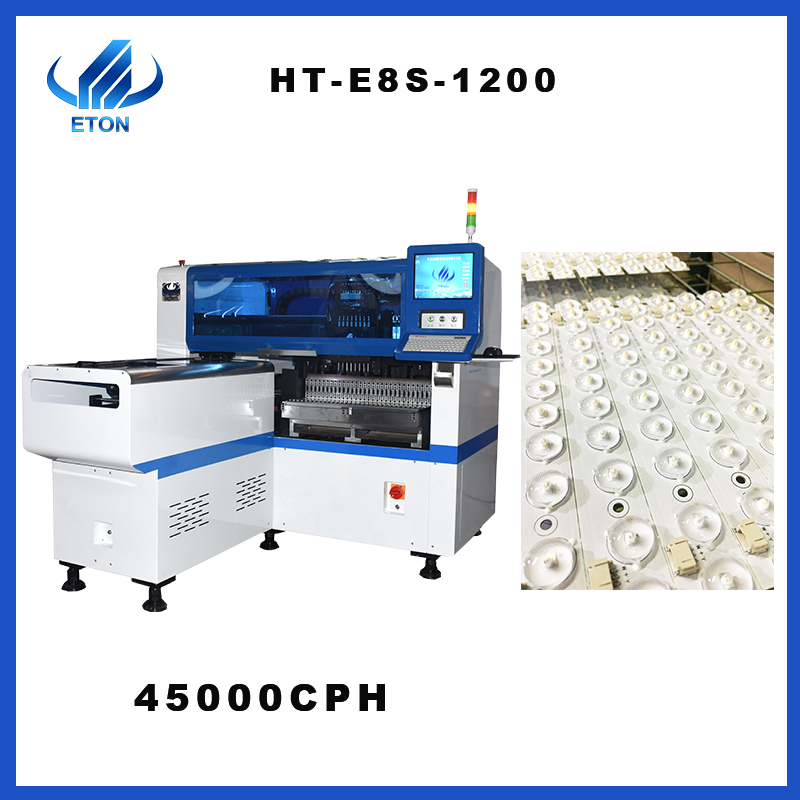

- Ultra high speed capability: Adopt high-end magnetic linear motor, servo system and multi function modular head, optimum speed reach 45000 CPH;

- Adopt High speed multi modular head, apply to ultra small chip 0201~10 mm large chip, wide component range;

- Brand new flight vision camera: Improve recognition performance, size up to 10mm*10mm;

- Vacuum sensing device: Each placement head with independent detection function, which improves the stability of the equipment and the reliability of the product;

- Off-line programming, save time of changeover cycle;

- Software AI intelligent learning function and automatic optimization function.

- Brand new self-developed high precision placement head;

- High-speed precision head flight vision camera capture the image of placement accordingly, improve placement performance;

-

-

- Single module magnetic linear motor multifunctional pick and place machine.

- Mounting components:LED chip, capacitors, resistors, lens, IC, shaped components, etc.

- Component: Min. Size 0402, Max. Height 15mm.

- Application: Power driver, electric board, lens, DOB bulb, linear bulb, household appliance etc.

-

Dimension

2550*1650*1550mm

PCB length width

Max:1200*500mm

Min:100*100mm

No.of feeders station

28 PCS single module

No.of head

12 PCS single module

-

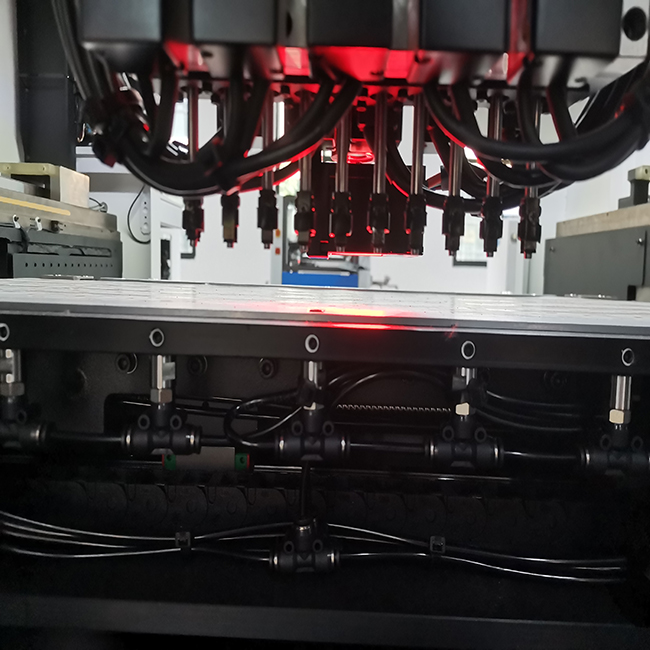

Magnetic linear motor is adopted to make the production fast, efficient and accurate

Drag chain imported form Germany, IGUS brand

With camera system, automatic identification and mark correction to ensure accurate and efficient mounting

The machine software is independently developed by ETON

-

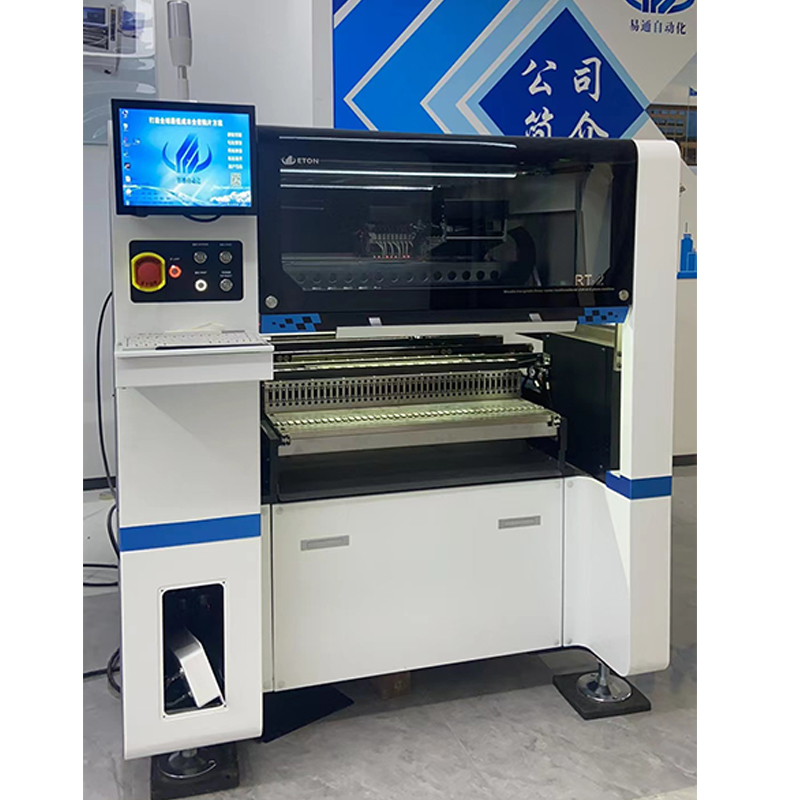

RT-1 can mounted all kinds of components,from 17 mm to 0402

RT-1 has 2 sets of camera to achieve flight identification and Mark correction

RT-1 can achieve group to pick and separate to place, separate to pick and separate to place.

-

20 heads, 64 feeders station, capacity reach 80000 CPH

producing 2 different products at the same time

4 sets of camera: flight identification and Mark correction

RT-2 is equivalent to two RT-1 and the enhanced version of RT-1.

-