- Ultra high speed capability: Adopt high-end magnetic linear motor, servo system and multi function modular head, optimum speed reach 45000 CPH;

- Adopt High speed multi modular head, apply to ultra small chip 0201~10 mm large chip, wide component range;

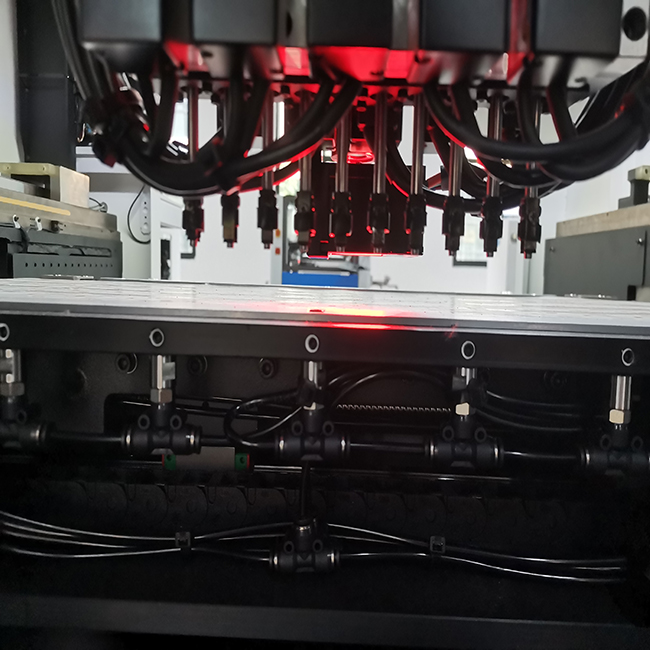

- Brand new flight vision camera: Improve recognition performance, size up to 10mm*10mm;

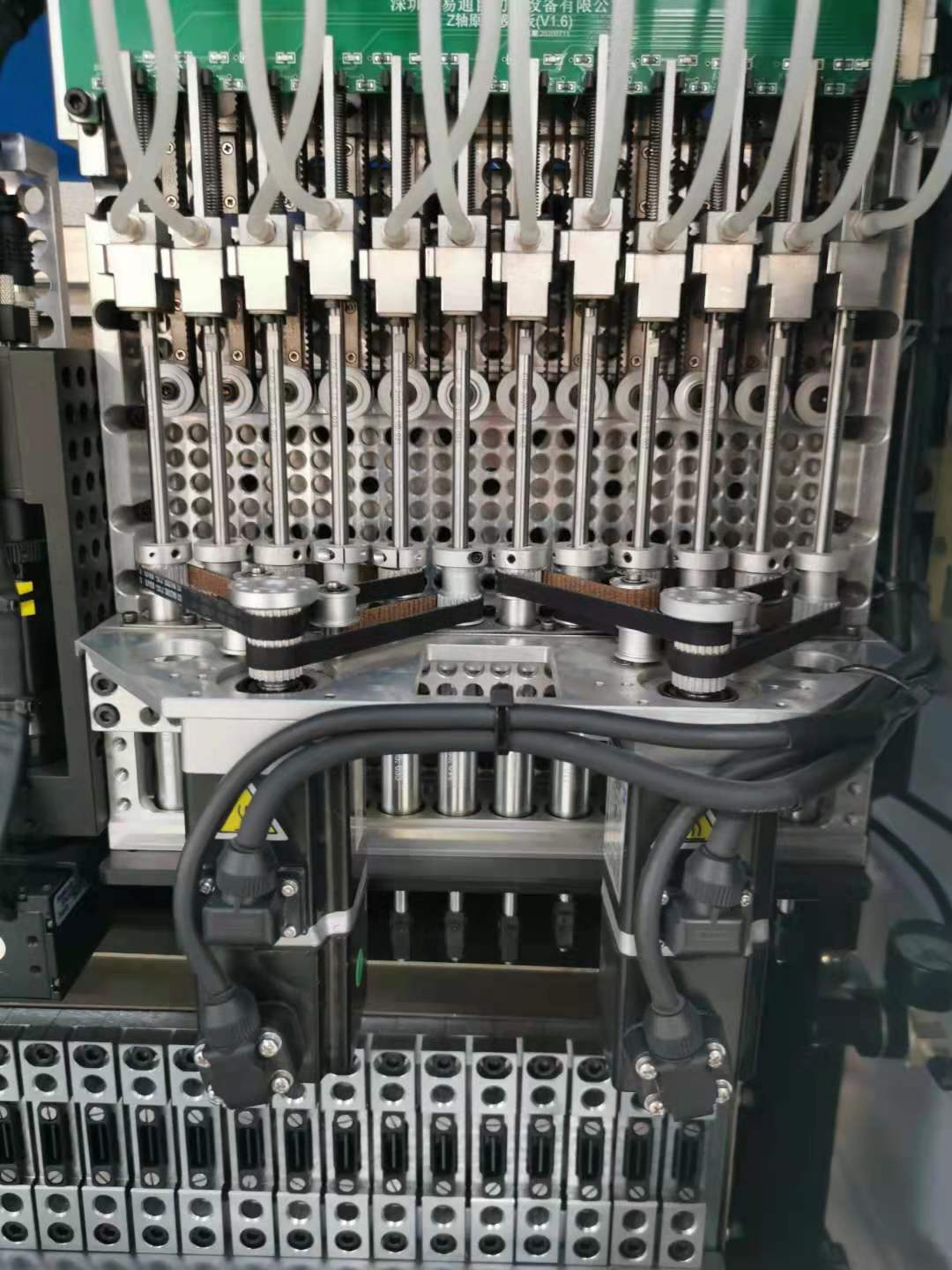

- Vacuum sensing device: Each placement head with independent detection function, which improves the stability of the equipment and the reliability of the product;

- Off-line programming, save time of changeover cycle;

- Software AI intelligent learning function and automatic optimization function.

- Brand new self-developed high precision placement head;

- High-speed precision head flight vision camera capture the image of placement accordingly, improve placement performance;

-

-

-

-

1. suitable for a variety of products: LED bulbs, street light, table light, down lights, power driver, electric board, lens,display screens and linear products, such as LED tube, flexible strip

2. the range of components: led chips, resistor, capacitor, IC, lens, shaped components etc.

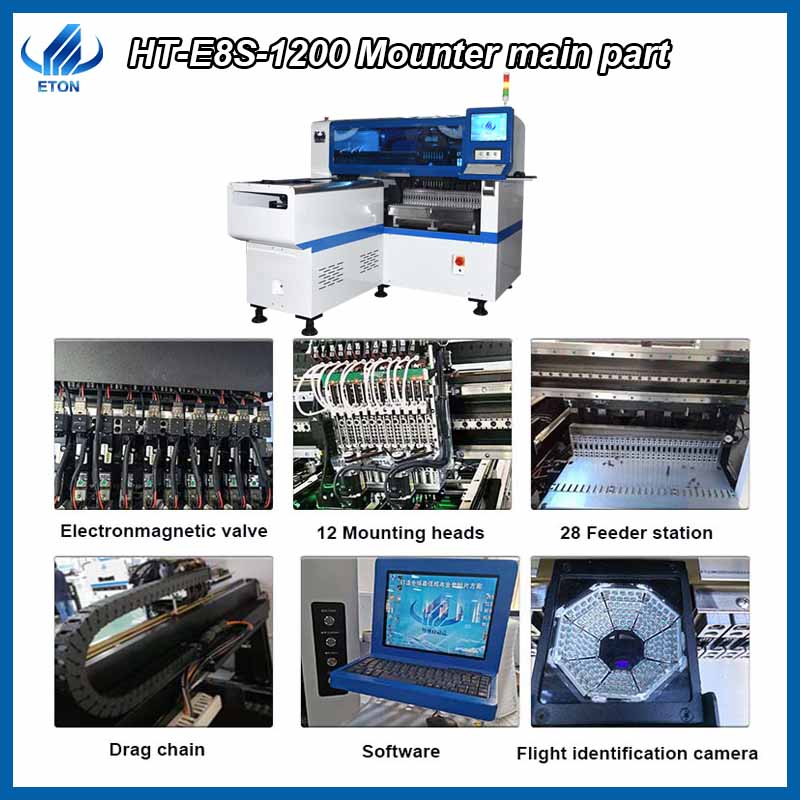

3. 12 PCS of heads, 28 PCS of feeders station, mounting speeds up to 45000 CPH.

4. electronic feeder feeding system, vision alignment flight identification, mark correction, non-stop material re-loading function,auto-optimization after coordinates generated.

-

1.HT-E8S-1200SMT Mounter belong to Single module magnetic motor multifunctional pick and place machine. 12 mounting heads, optimum mounting speed reached 45000 CPH.The actual production capacity should be determined according to the mounted products and the actual production situation.

2.The Max PCB Size:1200*500mm.As long as the length of the PCB board is within 1.2 meters, this machine can be achieved.

3.Mounting components:Led chip,capacitors,resistors,lens,IC,shape components(minsize 0402 max height 17mm)

4.Application:Power driver. Electric board. Lens. DOB bulb. linear bulb.Panel light.street light,tube etc.

-

1.RT-1:Single module magnetic linear motor multifunctional pick and place machine.

2.This machine equipped with 10 heads, which mounting speed reached 40000CPH.

3.The max PCB size:450*350mm.

4.It can mount minimum size 0402 components. And also can mount less than 22 MM high components. Including LED chips, resistors, capacitors, IC, shaped components, inductance, etc. 5.Suitable for small PCB products, Such as LED bulb. LED linear bulb, LED DOB bulb, LED street light, LED down-light, LED Driver and Small home appliance electronic boards, etc.

-

YT-202S is the latest placement machine. Suitable for mounting high-precision products,

the smallest components can be mounted 0201~40*40mm tape reel package and IC tray feeder

-

The machine is easy to operate and generally only takes five days. We will provide free online or offline teaching.

The beam adopts linear guide and grating ruler. Make the head do high-precision reciprocating motion, with high detection accuracy and fast response speed.

28 feeders can be placed, which can greatly satisfy the number of components placed by customers.Conducion to faster product output, better and more convenient.

-

-

- Apply to the 0.6m, 0.9m, 1.2m rigid PCB and 0.5m, 1m LED flexible strip, producing with 4 types materials at the same time with 250000 CPH capacity, available for board with any proportion of LED chip and resistor.

- Owing an exclusive technology of group picking and group placing, PCB size is 1200*330 can mount LED 3014/3020/3528/5050 or resistor, capacitor and bridge rectifiers, etc.

- Exclusive patent technology: Group to take and group to mount.

- IPC9850 capacity: 200000-250000 CPH

-

- Ultra high speed capability: Adopt high-end magnetic linear motor, servo system and multi function modular head, optimum speed reach 45000 CPH;

- Adopt High speed multi modular head, apply to ultra small chip 0201~10 mm large chip, wide component range;

- Brand new flight vision camera: Improve recognition performance, size up to 10mm*10mm;

- Vacuum sensing device: Each placement head with independent detection function, which improves the stability of the equipment and the reliability of the product;

- Off-line programming, save time of changeover cycle;

- Software AI intelligent learning function and automatic optimization function.

- Brand new self-developed high precision placement head;

- High-speed precision head flight vision camera capture the image of placement accordingly, improve placement performance;

-

No waiting for one-time placement under any lamp bead and resistor ratio.

Exclusive patented technology: group take group post.

Applicable PCB board size: MAX1200*330MM MIN 100*100MM