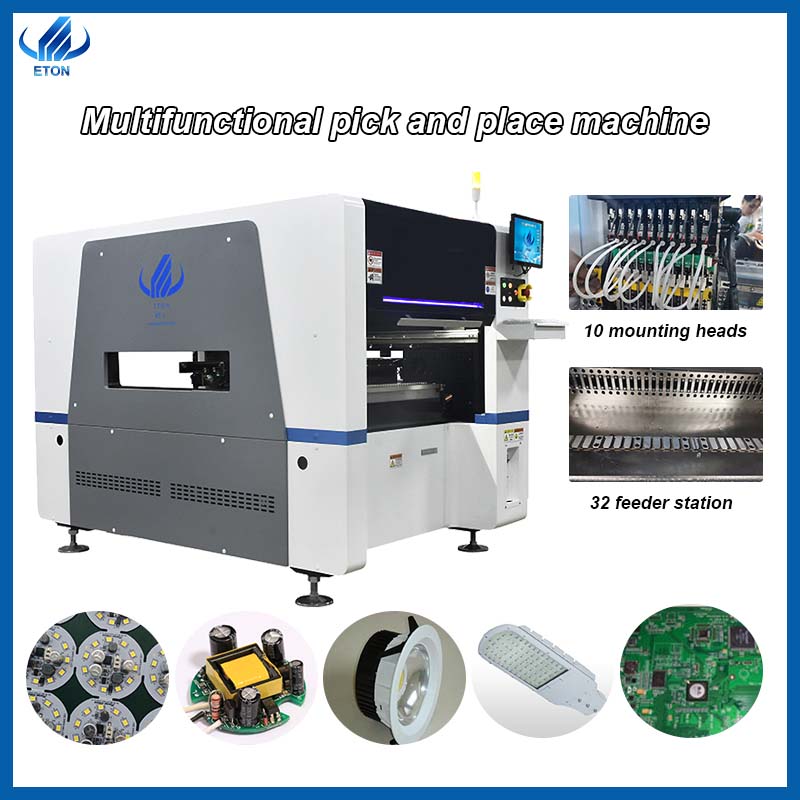

RT-1 is magnetic linear motor pick and place machine with 10 heads .Not only the speed can reach 4000 CPH , but also the mounting precision is plus or minus 0.04 mm.And the power consumption is 4 KW.

-

-

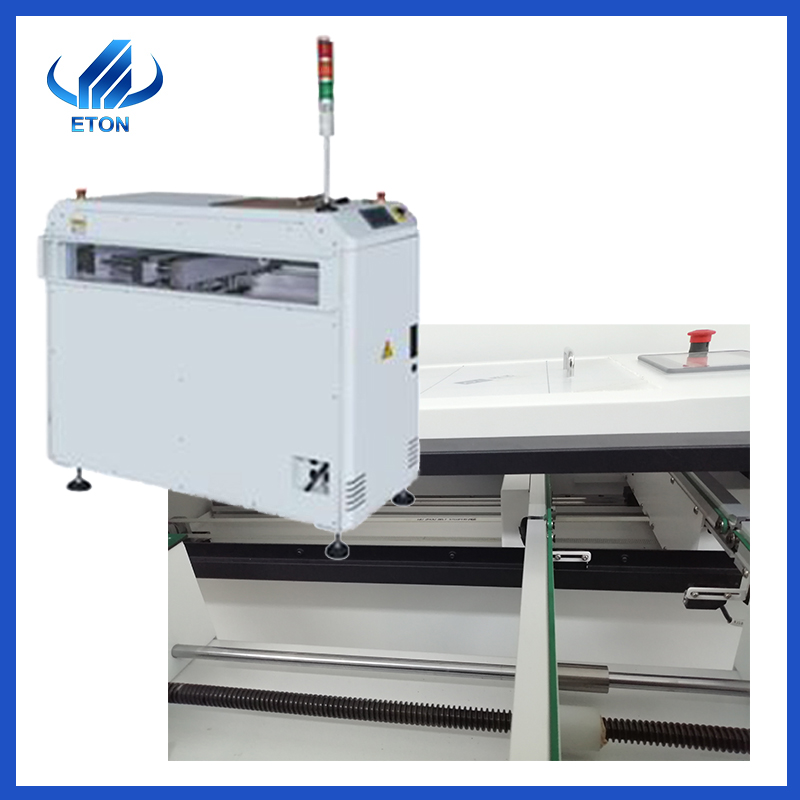

1.Flexible application of single load shifting, in accordance with the requirements of front and back end process docking, PCBA can be set to 0-180 degrees

2.Self-feeding, cutting, milling cutter replacement, finished material discharge, waste collection, fully automated production operations

3.The finished product can be discharged by belt, track and fixture

-

-

-

1 The unique advanced long life heating system

(1)The heating system adopt the Swedish nickel heater with efficiency and energy-saving. The peak wave length of the radiation power is 4UM with curved surface reflector to the rising temperature speed, improve the thermal efficiency. And the special forced-air circulation system make PCB and the component heated uniform and eliminate the "shadow effect" completely.

-

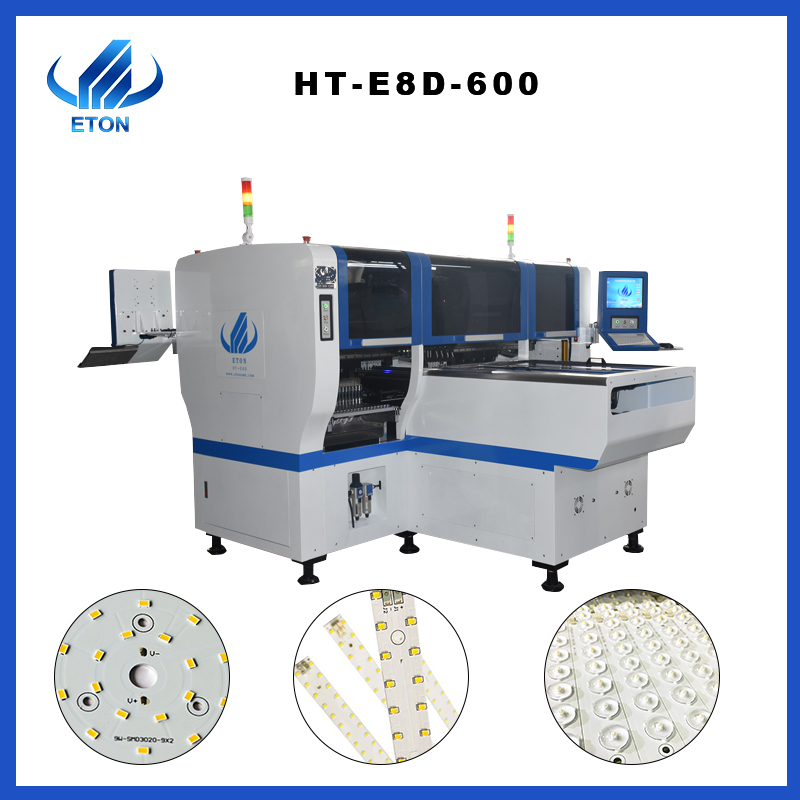

(1).HT-E8D-600:Double module magnetic motor multifunctional pick and place machine.

Dual system, dual module multifunctional mounter to produce two different products at the same time.

(2).24 placements heads, The optimum mounting speed reached 90000 CPH.The actual production capacity should be determined according to the mounted products and the actual production situation.

-

- Mounting components: LED chip, resistor, capacitor,IC,shaped components etc

- Component: min size 0402 max height 15mm

- Application: power driver, electric board,lens, DOB bulb, linear bulb, household appliance etc

-

-

-

-

Machine Function

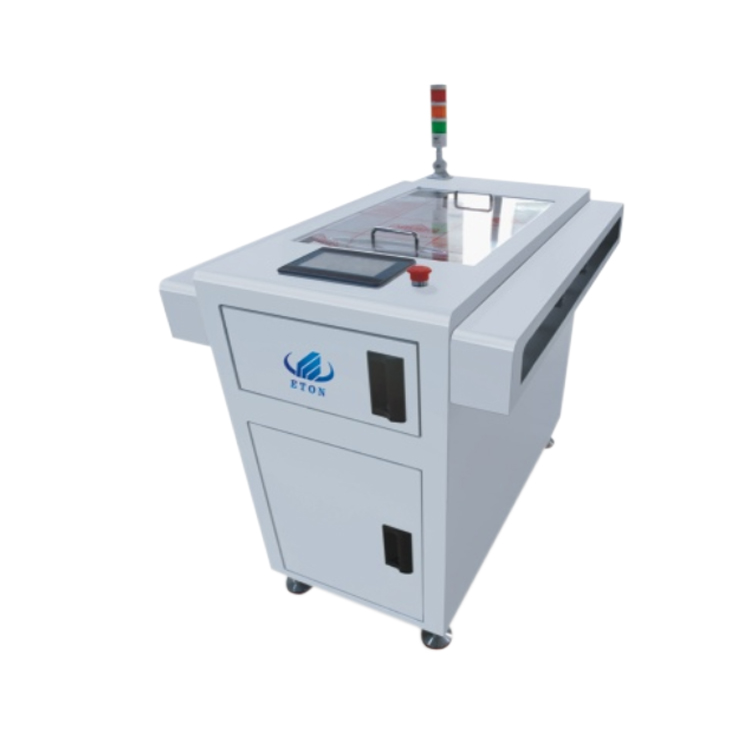

The equipment(PCB translational machine) is used to change the conveying direction of circuit board in the production line, scattered or assembled

-