-

-

-

- Mounting components: LED chip, resistor, capacitor,IC,shaped components etc

- Component: min size 0402 max height 15mm

- Application: power driver, electric board,lens, DOB bulb, linear bulb, household appliance etc

-

- Mounting components: LED chip, resistor, capacitor,IC,shaped components etc

- Component: min size 0402 max height 15mm

- Application: power driver, electric board,lens, DOB bulb, linear bulb, household appliance etc

-

- Mounting components: LED chip, resistor, capacitor,IC,shaped components etc

- Component: min size 0402 max height 15mm

- Application: power driver, electric board,lens, DOB bulb, linear bulb, household appliance etc

-

-

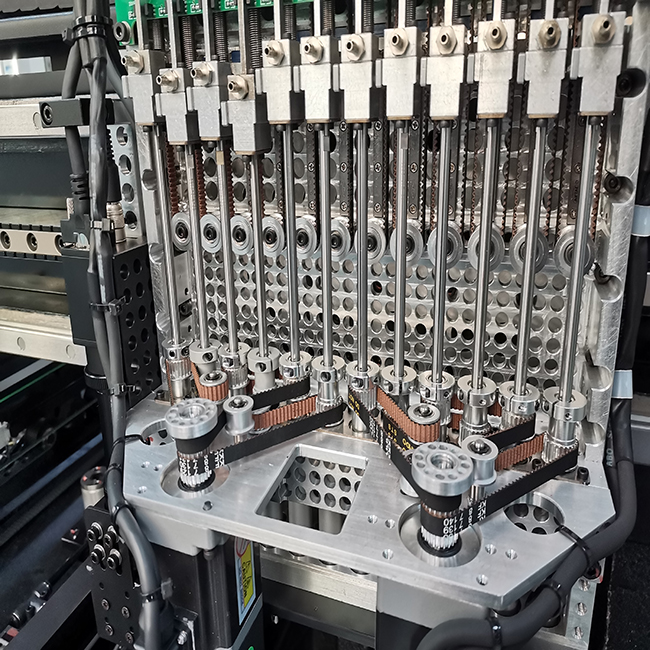

1.Brand new self-developed high-precision placement head

2.High-speed precision head flight vision camera capture the image of placement accordingly.improve the speed and accuracy of placement 3

3.10 heads,The placement head adopt independent vacuum detection,improve placement performance the optimum speed reached 40000cph.

4.Components:Apply to 0201~40*40mm tape reel package.

Improve recognition performance, size up to 40*40mm, apply to BGA or CSP etc

5.Off-line programming.save time of changeover cycle • Software Al intelligent learning function and automatic optimization function.

6.Feeder system:Intelligent electric feeder

-

Diverse functions, efficient production.High-speed modular head. Eton tech adjustable placement head, apply to 3014/3020/2835/5050/resister, capacitor, bridge rectifier etc. The optimal capacity can reach 500000CPH.

-

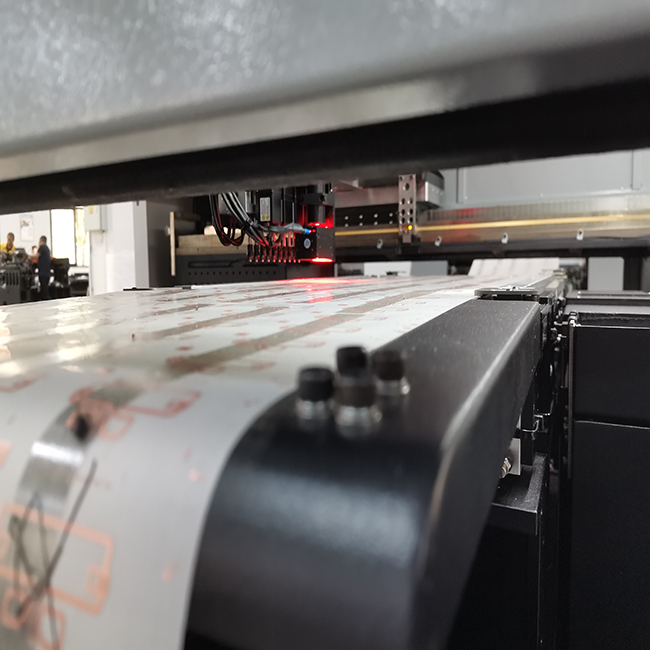

Dual purpose professional high speed mounter, 2~4 type of capacity reach 150000CPH

Vision alignment, Mark correction

Components: LED 3014/3020/3528/5050 and capacitors, resistors, bridge rectifiers, etc

Application: flexible strip, LED tube, panel light, etc

-

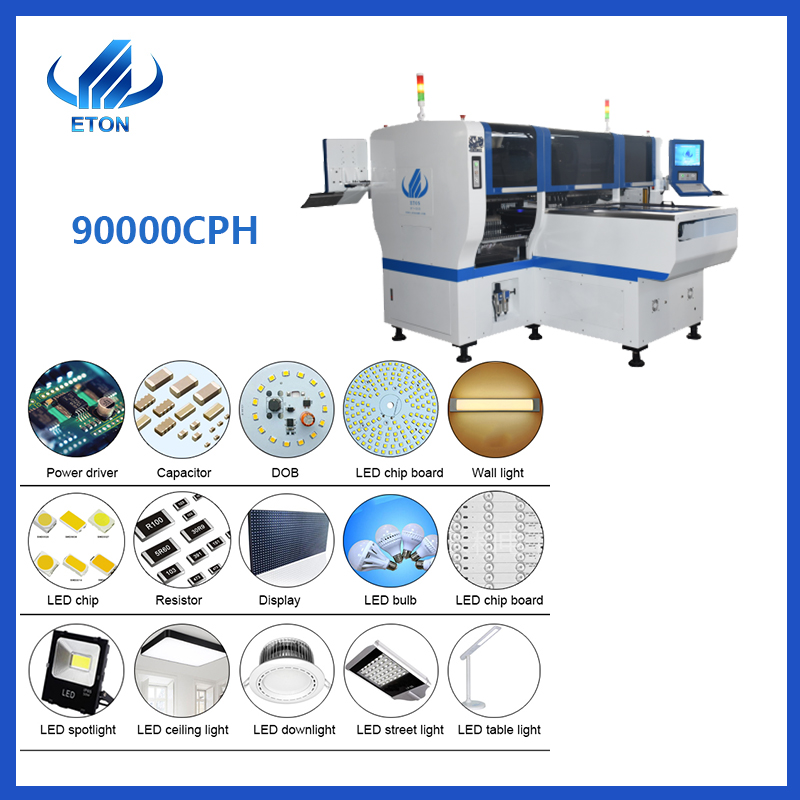

(1).HT-E8D-600:Double module magnetic motor multifunctional pick and place machine.

Dual system, dual module multifunctional mounter to produce two different products at the same time.

(2).24 placements heads, The optimum mounting speed reached 90000 CPH.The actual production capacity should be determined according to the mounted products and the actual production situation.

(3).Mounting components:Led chip,capacitors,resistors,lens,IC,shape components(min size 0402 max height 17mm)etc.Max PCB Size:600*300mm

(4)Adopted Electronic feeder feeding system,non-stop material re-loading function.This machine equipped with 2 sets of imported camera,vision for the flight identification,which greatly improve the placement the placement accuracy of the machine.

-

-