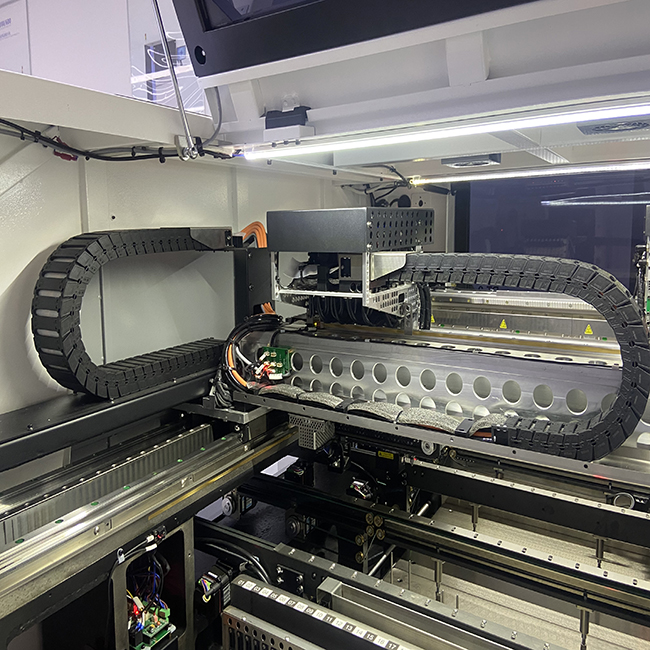

*Double side docking cart slot 32PCS,tape reelpackages: 64PCS (single side docking catslot 16PCS,tape reel packages: 32PCS),freely switching between docking cart and IC tray feeder(IC tray feeder:Option).

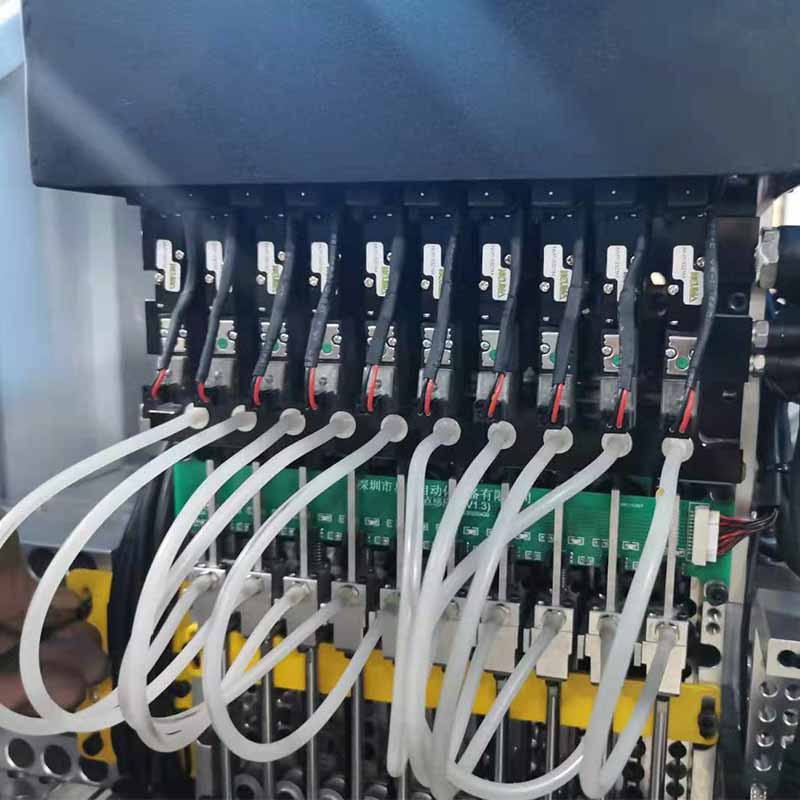

*Support YT series double head intelligent electrictape reel feeder,by optically correcting the feedingposition of the component,it can achieve stable,accurate and high-speed feeding.

*Support multi-layer tray feeder(IC tray feeder)installment,freely switching between dockingcart and IC tray feeder.