The PCB size: max 500*350mm min50*50mm

The optimal capacity can reach 40000CPH

Apply to 0201~40*40mm packages and IC etc.

Non replace modular head

The PCB size: max 500*350mm min50*50mm

The optimal capacity can reach 40000CPH

Apply to 0201~40*40mm packages and IC etc.

Non replace modular head

The PCB size: max 500*350mm min50*50mm

The optimal capacity can reach 40000CPH

Apply to 0201~40*40mm packages and IC etc.

Non replace modular head

|

Dimension |

2550*1650*1550mm |

|

PCB length width |

Max:1200*500mm Min:100*100mm |

|

No.of feeders station |

28 PCS single module |

|

No.of head |

12 PCS single module |

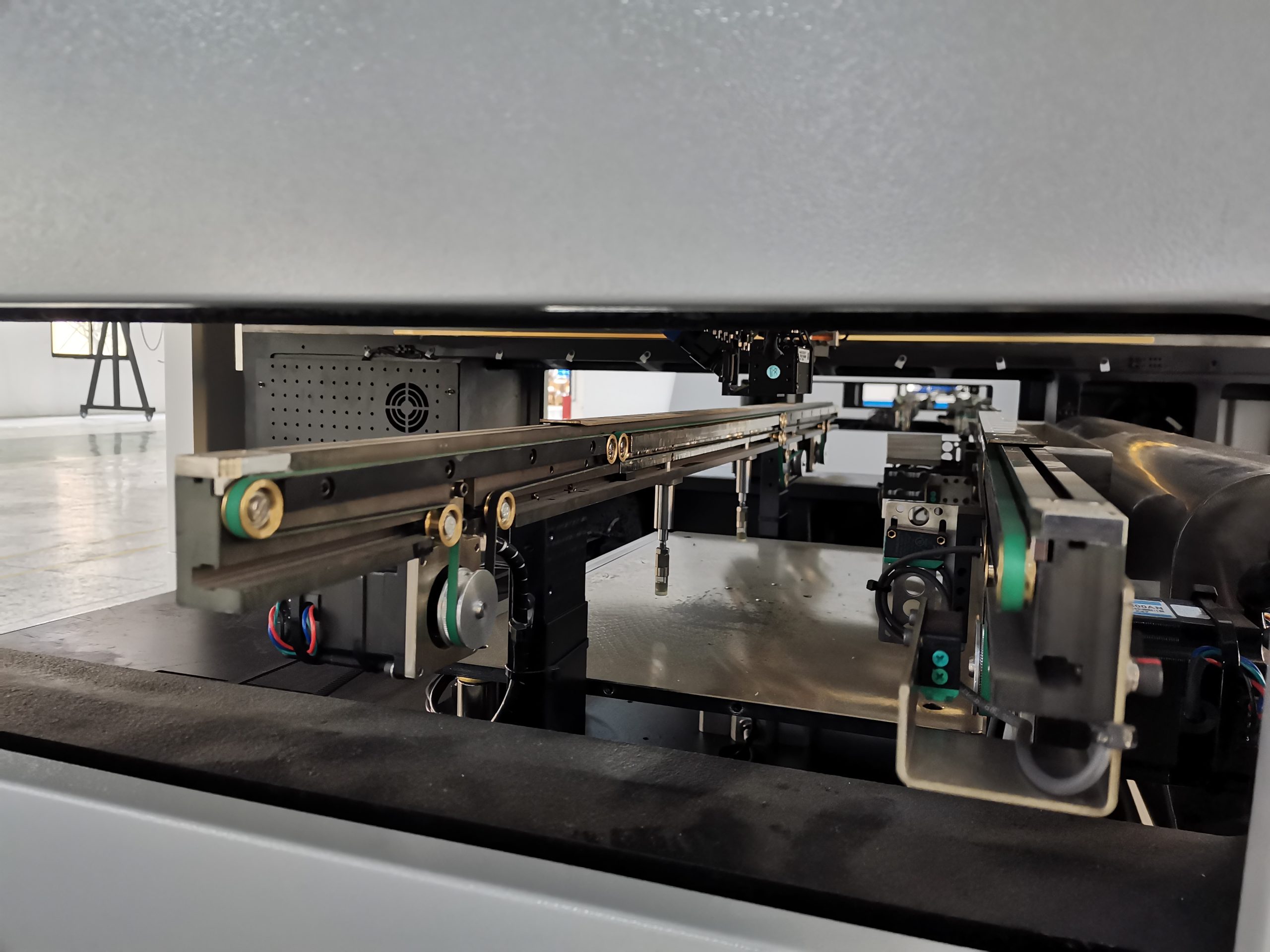

Magnetic linear motor is adopted to make the production fast, efficient and accurate

Drag chain imported form Germany, IGUS brand

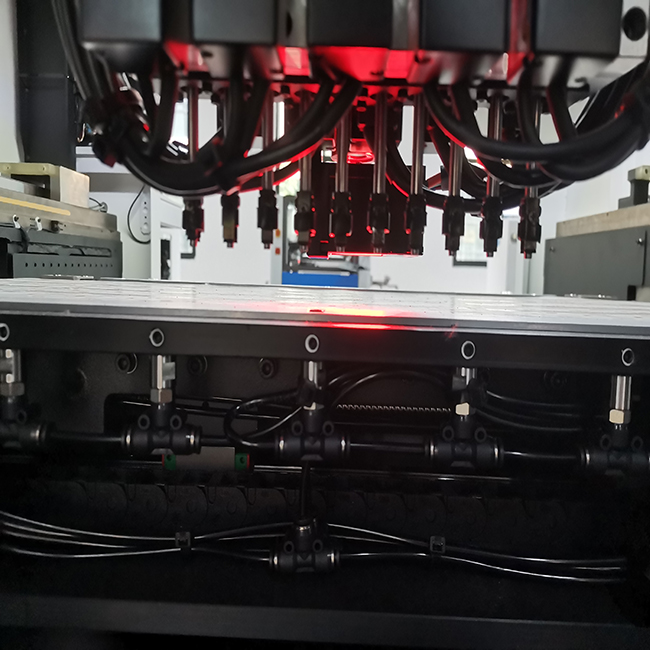

With camera system, automatic identification and mark correction to ensure accurate and efficient mounting

The machine software is independently developed by ETON

RT-1 can mounted all kinds of components,from 17 mm to 0402

RT-1 has 2 sets of camera to achieve flight identification and Mark correction

RT-1 can achieve group to pick and separate to place, separate to pick and separate to place.

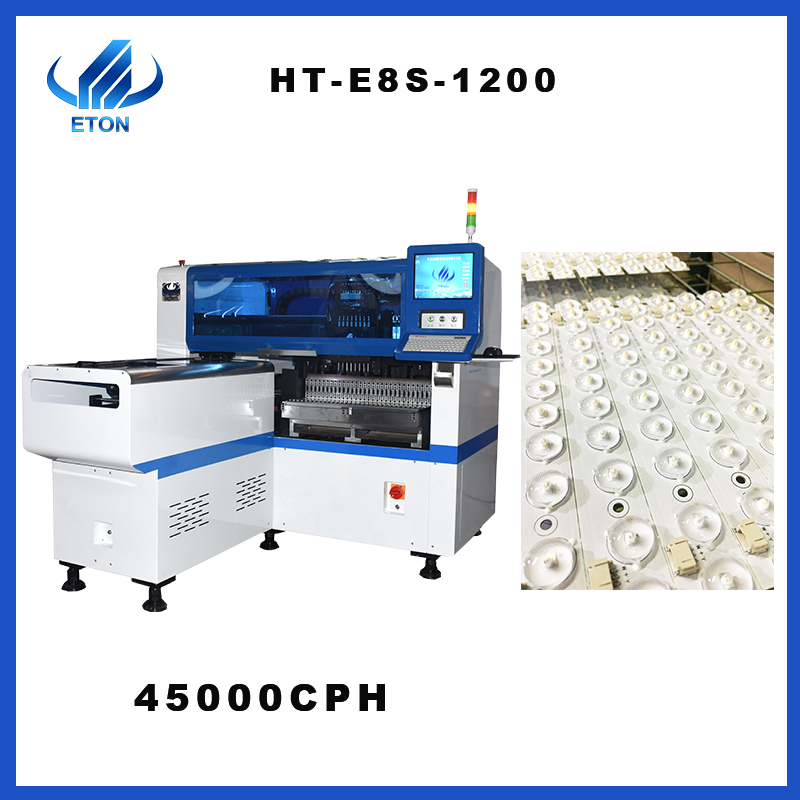

1.It has 12PCS head and the mounting speed can reach 45000CPH.

2.The maximum PCB size is 1200*500mm.Min size 0402.

3.Group picking and separately placing,separately picking and separately placing.

1.It has 12PCS head and the mounting speed can reach 45000CPH.

2.The maximum PCB size is 1200*500mm.Min size 0402.

3.Group picking and separately placing,separately picking and separately placing.

The machine is easy to operate and generally only takes five days. We will provide free online or offline teaching.

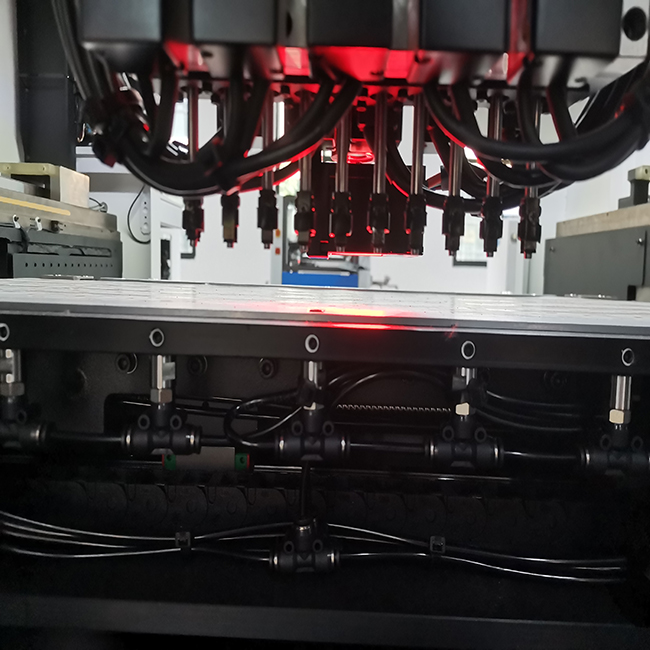

The beam adopts linear guide and grating ruler. Make the head do high-precision reciprocating motion, with high detection accuracy and fast response speed.

28 feeders can be placed, which can greatly satisfy the number of components placed by customers.Conducion to faster product output, better and more convenient.

1. New model RT-1 has increased the number of feeder station from 32 PCS to 42 PCS. To some extent, It is improving production efficiency and saving labor.

2. The X axis uses high-end magnetic linear motor, which has higher accuracy and faster speed. Each head of Z axis is independently controlled by servo motor to ensure accurate mounting.

3. The head structure is independent research and development by ETON, the structure and material are unique. and the mounting height is adjustable,up to 20 mm. It can be applied to many high DOB components and has wider range of applications.

1.Magnetic linear LED high-speed pick and place machine, Producing with 4 types materials at the same time

2.Available for board with any proportion of LED chip and resistor.

3.Dual arm four module, 17 nozzles for each mounting part, part A or part B can be mounted separately or synchronously.