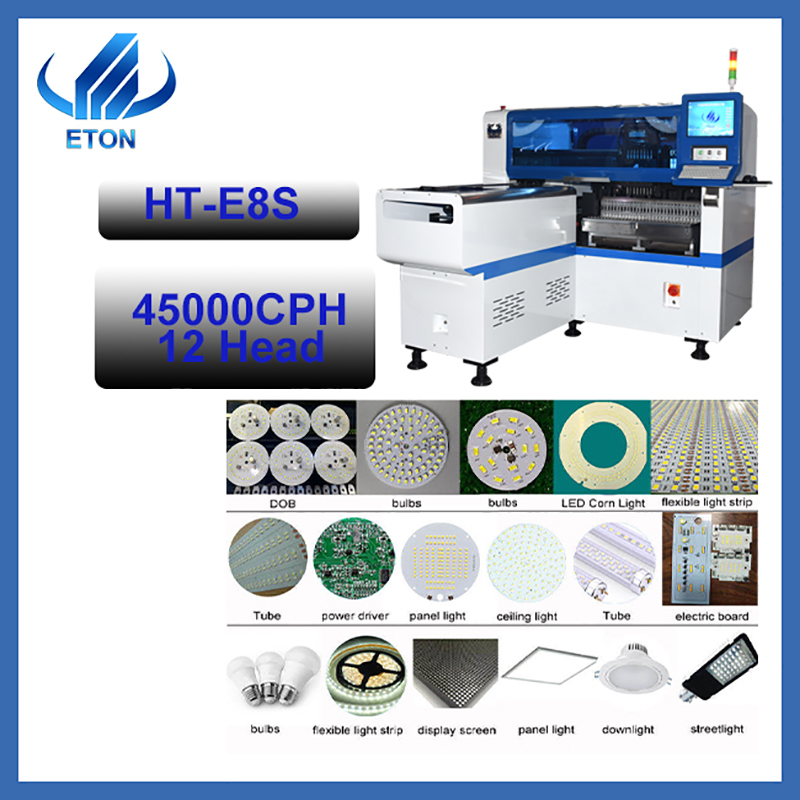

1.It has 12PCS head and the mounting speed can reach 45000CPH.

2.The maximum PCB size is 1200*500mm.Min size 0402.

3.Group picking and separately placing,separately picking and separately placing.

1.It has 12PCS head and the mounting speed can reach 45000CPH.

2.The maximum PCB size is 1200*500mm.Min size 0402.

3.Group picking and separately placing,separately picking and separately placing.

1.It has 12PCS head and the mounting speed can reach 45000CPH.

2.The maximum PCB size is 1200*500mm.Min size 0402.

3.Group picking and separately placing,separately picking and separately placing.

4.Vision alignment flight identification, Mark correction.

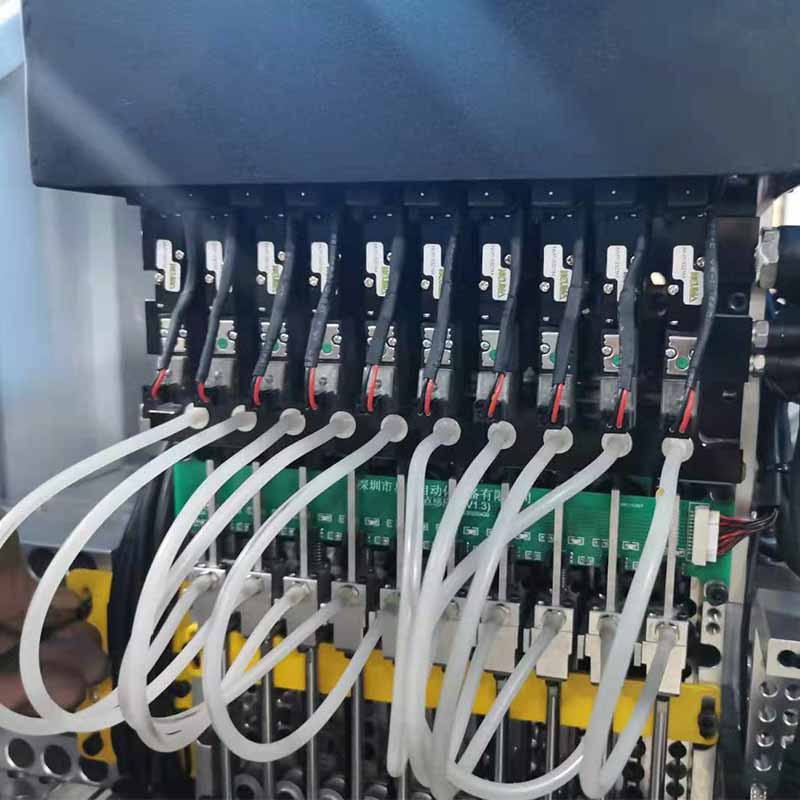

1.HT-E8S-1200 adopts the method of Vacuum adsorption to absorb components from the feeder station and then vacuum is released to mount at the specified position.

2.The tank chain wraps the line so as to reduce the line wear and prolong the service life.

3.Flight identification camera and MARK camera scan components and MARK points of PCB board bonding pad, with flight identification alignment, MARK correction and automatic optimization after coordinate generation.

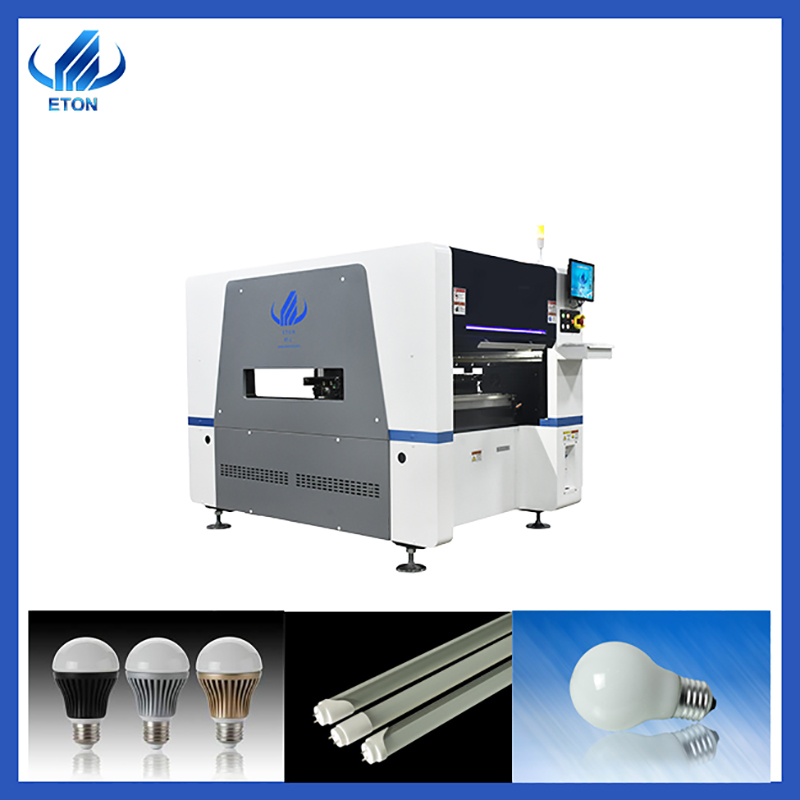

1.It has 12PCS head and the mounting speed can reach 45000CPH.

2.The maximum PCB size is 1200*500mm.Min size 0402.

3.Group picking and separately placing,separately picking and separately placing.

4.Vision alignment flight identification, Mark correction.

1.RT-1 machine belongs to Single module magnetic linear motor multifunctional pick and place machine

2.RT-1 machine equipped with 32 feeder stations and 10 nozzles,whic optimum mounting speed reached 40000cph.

3. It is applicable to the wider range of components, and can be mounted with resistors, capacitors, IC, bridge rectifiers, inductors, terminals, diodes, transistors, large-capacitance transformers, shaped components.

4.Software:Independent research and development by ETON, free upgrade whole lifetime, saving costs.

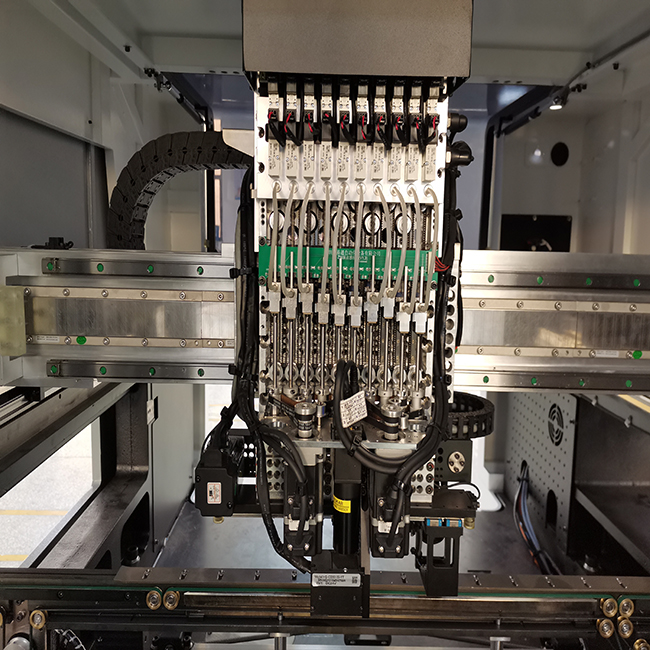

1.the mounting Head structure is independently developed with unique structure and material.

2.Flight identification system has Mark automatic correction, automatic compensation of mounting software.

3.Automatic feeding function is taking photos according to the identification camera, record the leakage position of PCB board, and realize automatic feeding by a separate feeding feeder .

E8D is a dual-mode multi-function machine. Each module has a set of programs to control independently.

24 pcs mounting head(support customized)

Max PCB Szie :1200*300mm(support customized)

Double module arms,can produce different products

With the increase of modules, the production capacity is twice that of E8S.

The optimal capacity is 90000CPH

The machine is easy to operate and generally only takes five days. We will provide free online or offline teaching.

The beam adopts linear guide and grating ruler. Make the head do high-precision reciprocating motion, with high detection accuracy and fast response speed.

28 feeders can be placed, which can greatly satisfy the number of components placed by customers.Conducion to faster product output, better and more convenient.

Double module can mounter two PCB board at the same time.

High precision placement speed up to 80000 CPH.

RT-2 can mounting LED chip,capacitors,resistors,IC,shaped components,etc.

Four sets cameras:Vision alignment flight identification,Mark correction.

The machine is easy to operate and generally only takes five days. We will provide free online or offline teaching.

The beam adopts linear guide and grating ruler. Make the head do high-precision reciprocating motion, with high detection accuracy and fast response speed.

28 feeders can be placed, which can greatly satisfy the number of components placed by customers.Conducion to faster product output, better and more convenient.

*Magnetic linear motor multifunctional pick and place machine

*Mounting components:LED chip、capacitors、resistors、IC、shaped components、etc.

*Electronic feeder feeding system.

*Vision alignment flight identification, Mark correction

*Auto-optimization after coordinates generated, etc.

*Magnetic linear motor multifunctional pick and place machine

*Mounting components:LED chip、capacitors、resistors、IC、shaped components、etc.

*Electronic feeder feeding system.

*Vision alignment flight identification, Mark correction

*Auto-optimization after coordinates generated, etc.