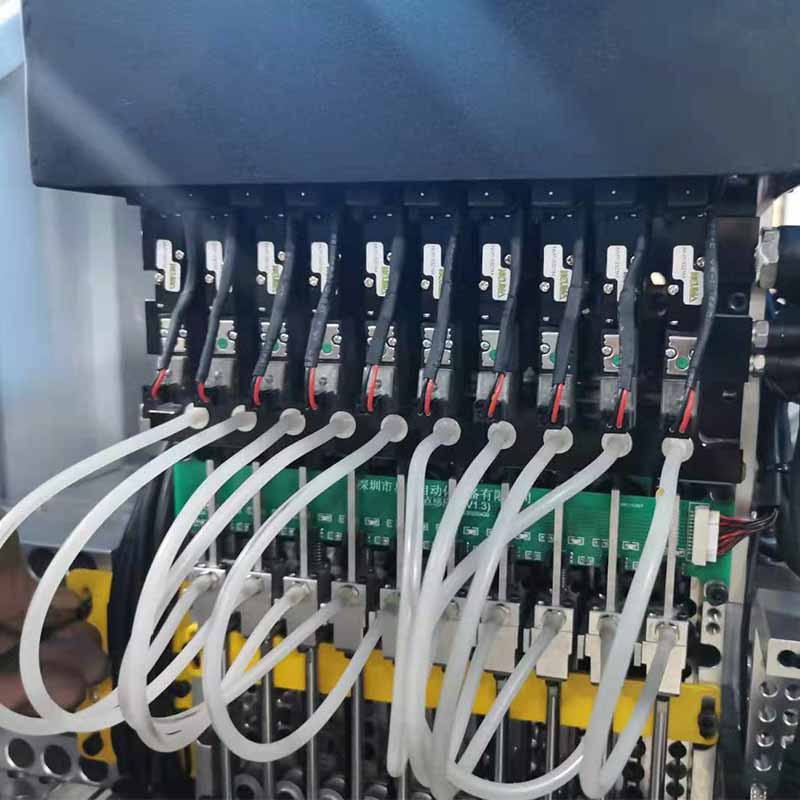

- Unique design component leaking detection and individual component refill function

- Component picking position can be adjusted according to PCB pad pitch, min 6.5mm.

- Adjust the conveying platform according to various roll to roll strip, range 250±10mm, the max length range is 1M per cycle.

- The range of feeding station is double of placement head, can produce four kinds of materials at the same time.

- The distance of feeder station can be flexibly adjusted to achieve group picking and group placing, so as to realize the function of two time picking and once placing.

- Flight recognition camera,no pause to detect the presence or absence of components, component adsorption state, prevent placement errors

-

-

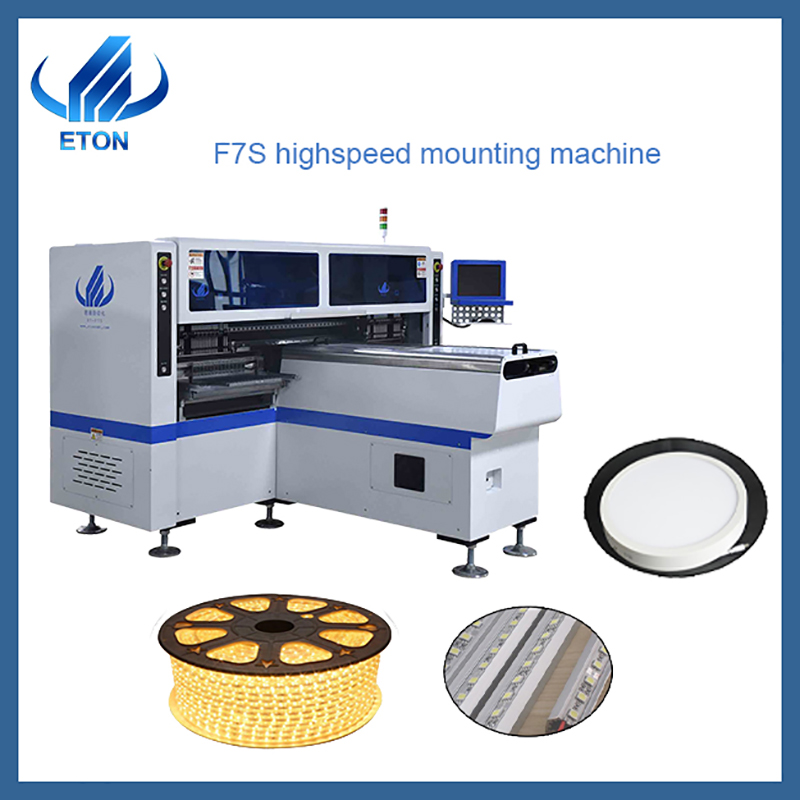

Dual arm professional high-speed mounter, mounting 2-4 types of materials at the same time capacity reach 180000 CPH. Apply to the 0.6m, 0.9m, 1.2m rigid PCB and 0.5m, 1m LED flexible strip, producing with 4 types materials at the same time with high capacity, available for board with any proportion of LED chip and resistor.

-

Producing with Producing 4 types materials at the same time with high capacity, available for 5M, 50M or any length of Flexible strip and Roll to roll.

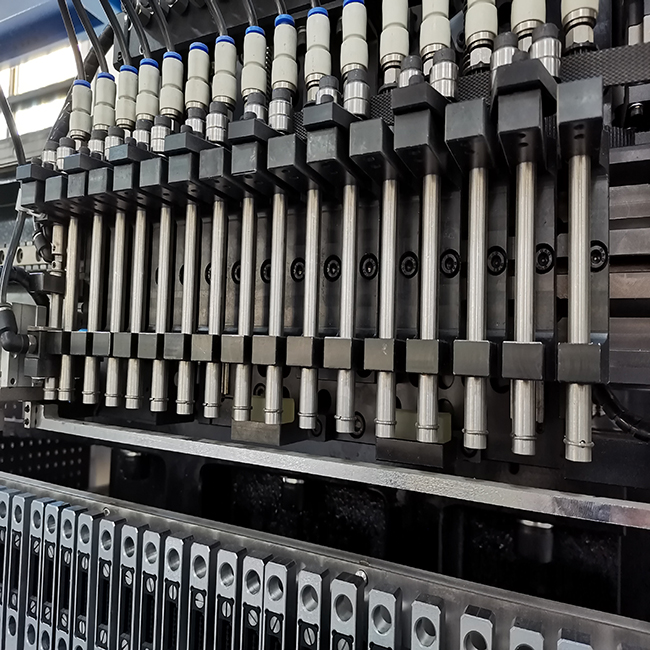

Dual arm four module, 17 nozzles for each mounting part, part A or part B can be mounted separately or synchronously.

Calibration automatically, high precision, available for RGB.

Exclusive patent technology: Group to pick and group to mount.

-

The fastest placement speed can reach 150000CPH, suitable for linear LED light products

34 nozzles, 68 feeders, affordable price, powerful function, high quality follow-up service

Equipped withETON's exclusive patented technology,Influenced the market price of LED lights.

-

Double module can mounter two PCB board at the same time.

High precision placement speed up to 80000 CPH.

RT-2 can mounting LED chip,capacitors,resistors,IC,shaped components,etc.

Four sets cameras:Vision alignment flight identification,Mark correction.

-

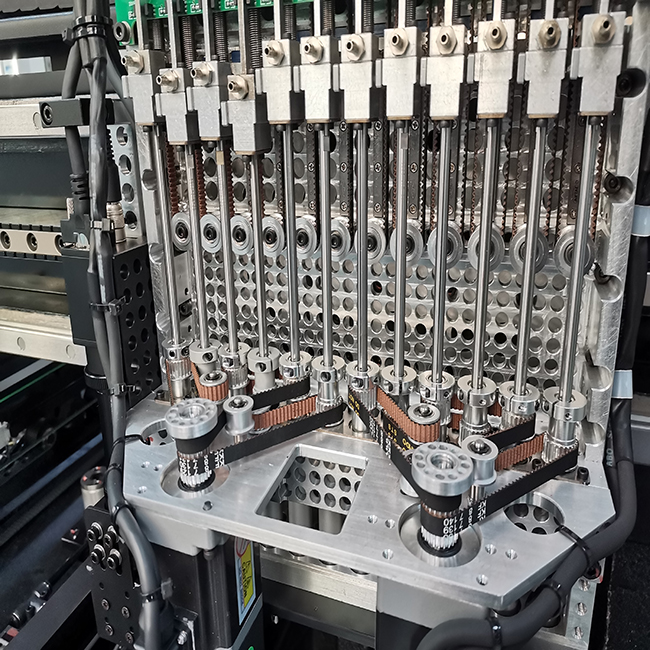

- Adopt High speed multi modular head, apply to ultra small chip 0201~10*10mm large chip, widercomponent range;

- Vacuum sensing device: Each placement head with independent detection function, which improves the stability of the equipment and the reliability of the product;

- Ultra high speed capability: Adopt high-end magnetic linear motor, servo system and multi function modular head, the capacity increased by 25% compared with traditional machine, optimum speed reach120000 CPH;

-

- Adopt High speed multi modular head, apply to ultra small chip 0201~10*10mm large chip, widercomponent range;

- Vacuum sensing device: Each placement head with independent detection function, which improves the stability of the equipment and the reliability of the product;

- Ultra high speed capability: Adopt high-end magnetic linear motor, servo system and multi function modular head, the capacity increased by 25% compared with traditional machine, optimum speed reach120000 CPH;

-

*Dual arm professional high-speed SMT machine.

*Producing 2-4 types materials at the same time.

*Vision alignment ,Mark correction.

*The mounting speed can reach 180000CPH.

-

- Adopt High speed multi modular head, apply to ultra small chip 0201~10 mm large chip, widercomponent range;

- Brand new flight vision camera: Improve recognition performance, size up to 10mm*10 mm;

- Vacuum sensing device: Each placement head with independent detection function, which improves the stability of the equipment and the reliability of the product;

- Optimum speed reach 90000 CPH;

-

-

- Adopt High speed multi modular head, apply to ultra small chip 0201~10 mm large chip, widercomponent range;

- Brand new flight vision camera: Improve recognition performance, size up to 10mm*10 mm;

- Vacuum sensing device: Each placement head with independent detection function, which improves the stability of the equipment and the reliability of the product;

- Optimum speed reach 90000 CPH;

-

The machine is easy to operate and generally only takes five days. We will provide free online or offline teaching.

The beam adopts linear guide and grating ruler. Make the head do high-precision reciprocating motion, with high detection accuracy and fast response speed.

48 feeders can be placed, which can greatly satisfy the number of components placed by customers.Conducion to faster product output, better and more convenient.