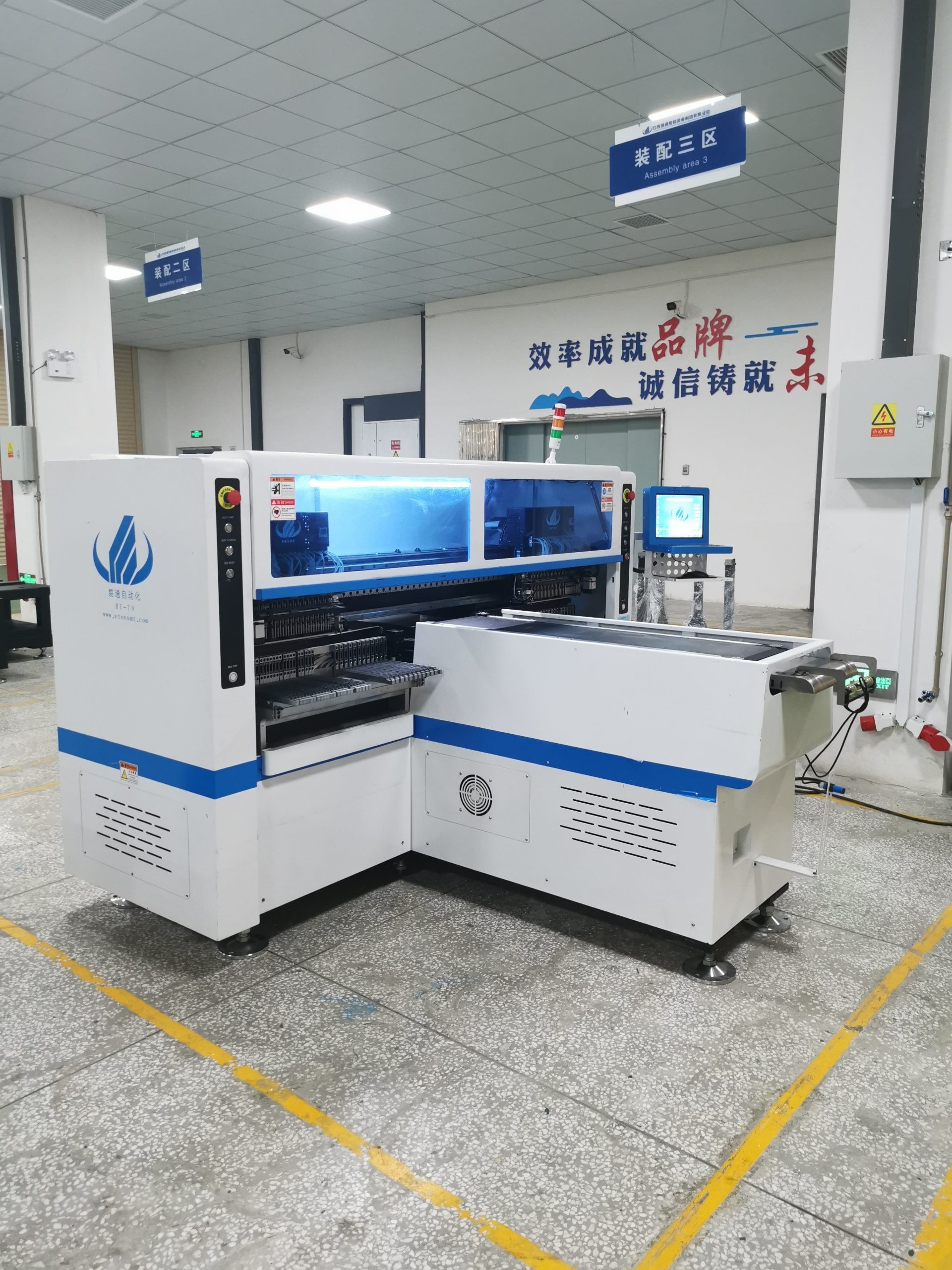

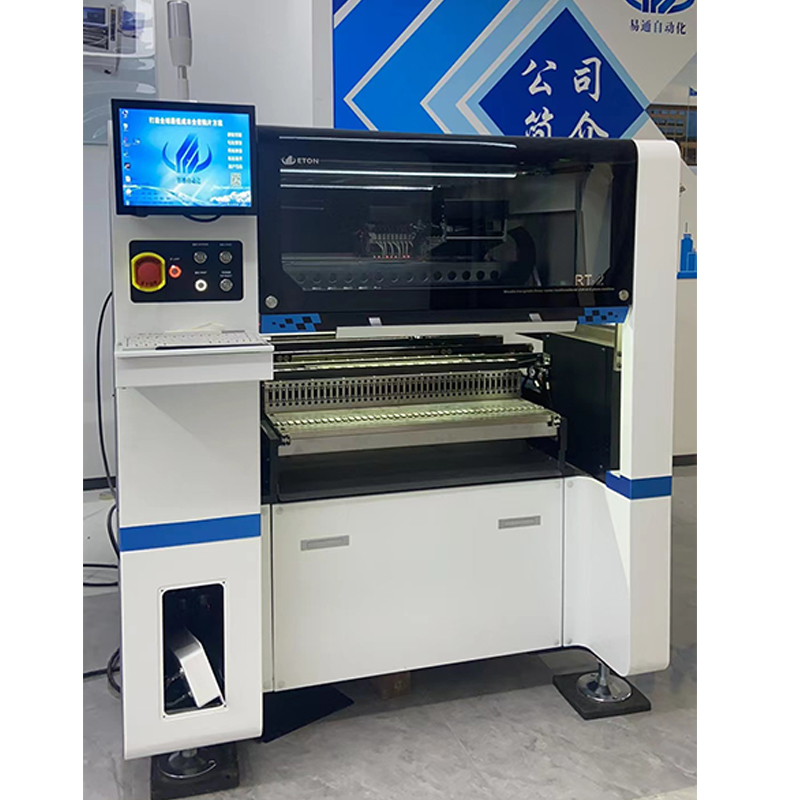

1.Magnetic linear motor and servo motor professional high speed pick and place machine, produce 2 - 4 different types of materials at the same time.

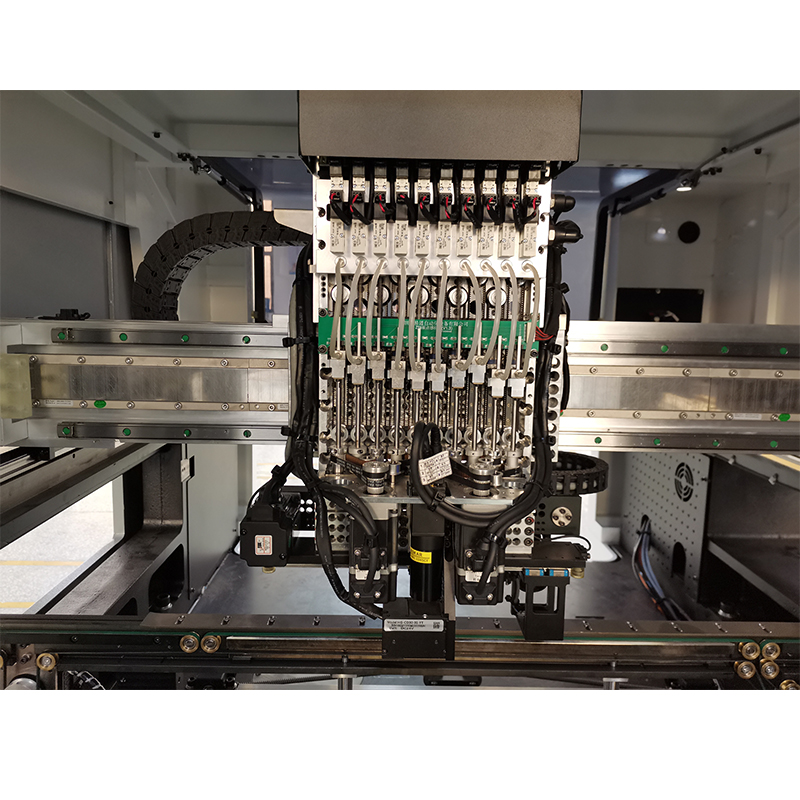

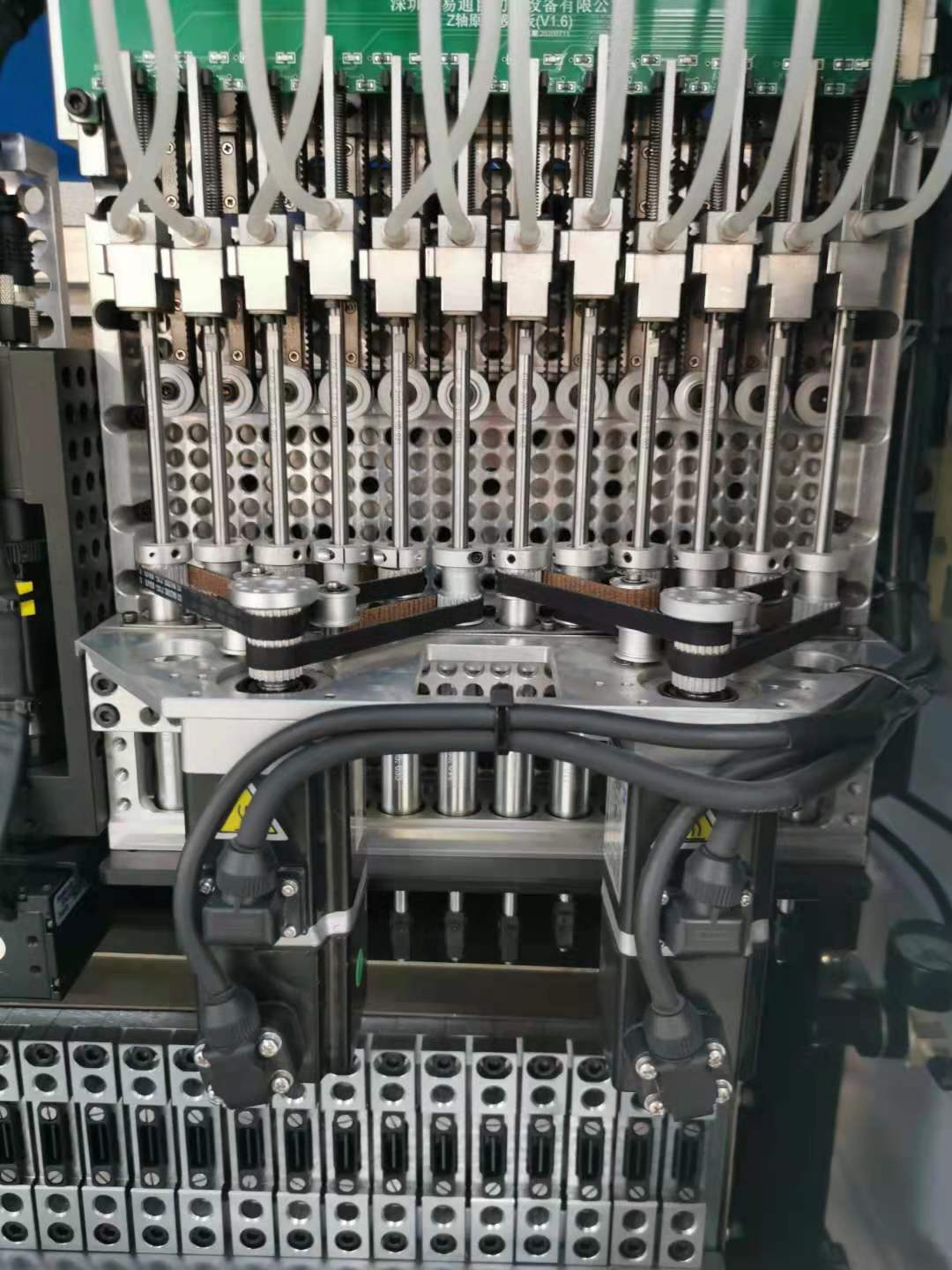

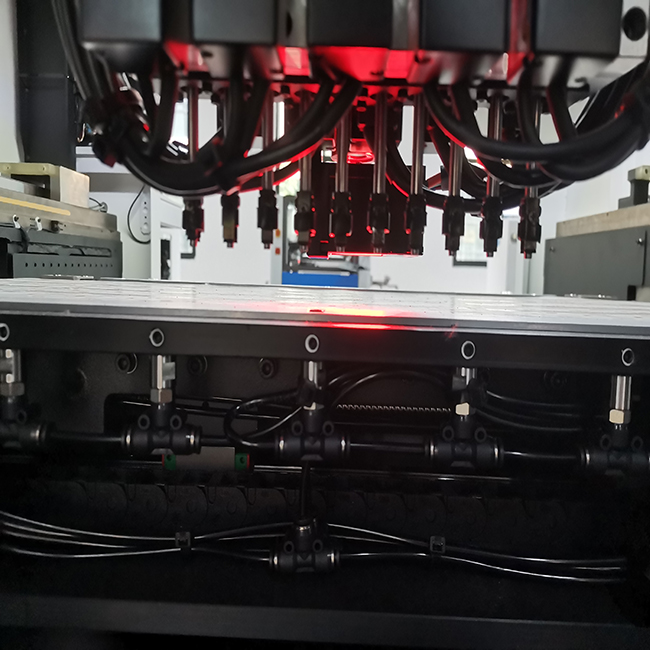

2. 34 PCS of heads, 68 PCS of feeders station, two mounting heads, each mounting head has 17 nozzles, Every mounting head can be mounted separately or synchronously.

3. HT- F7S has the function of calibration automatically and high precision. It is also available for RGB.