- Easy operation with Windows 7 system in Chinese and English language,

very convenient to use - 2 sets the high-resolution camera for accurate vision alignment correction

- a precision electric feeder with double motors

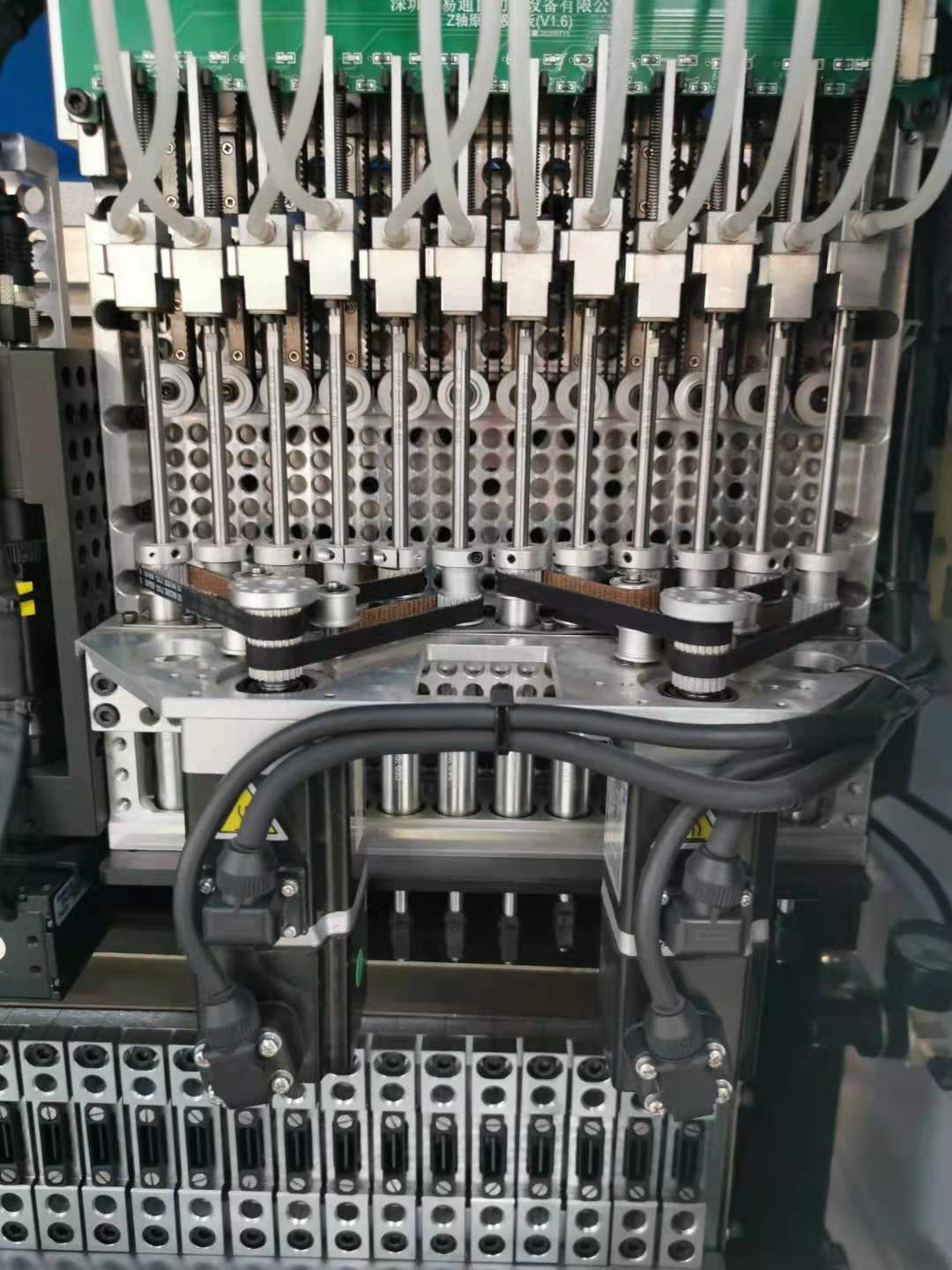

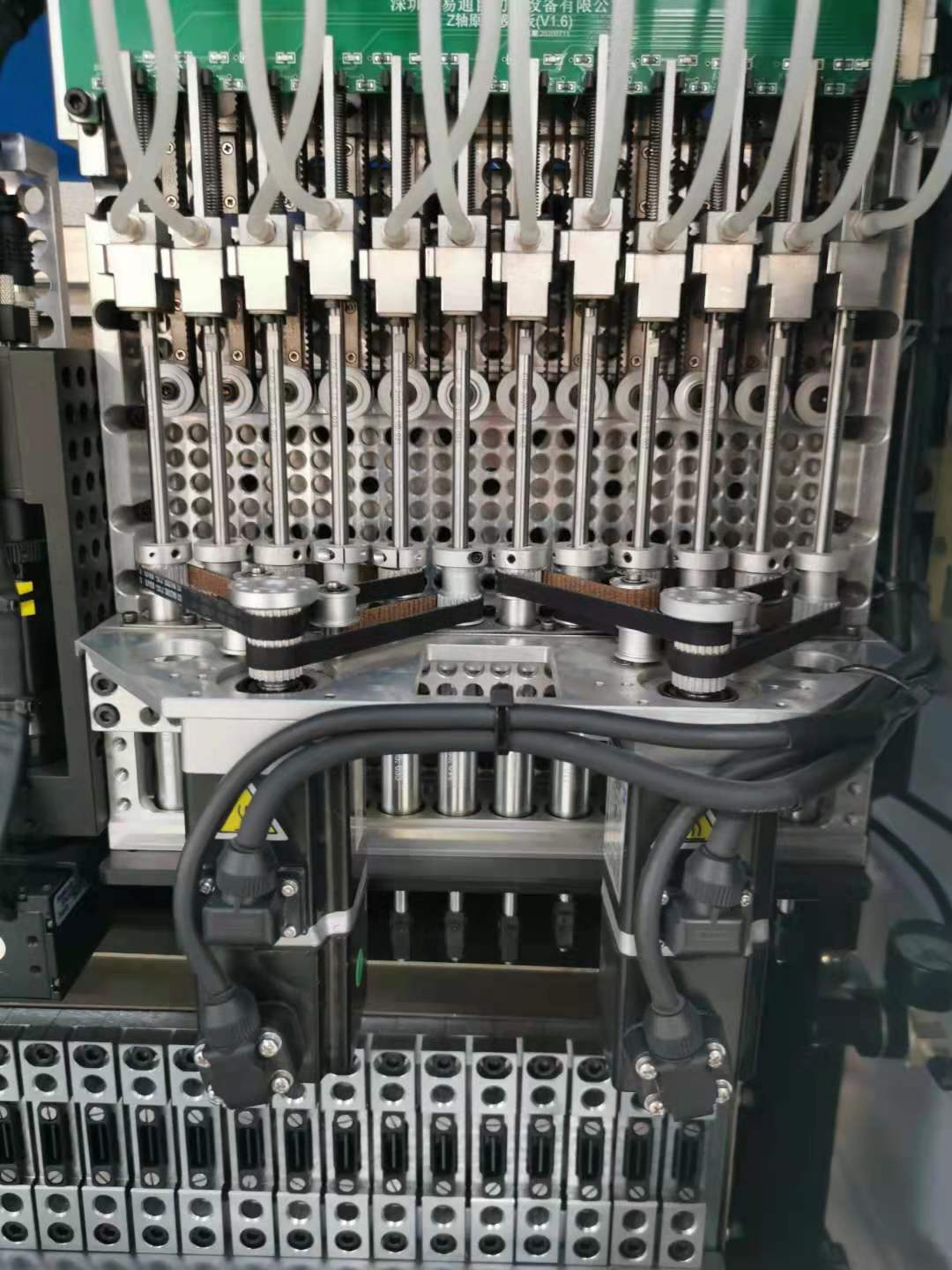

Single module and 1 mounting head, total has 12 heads, each head is independently controlled by one servo motor;

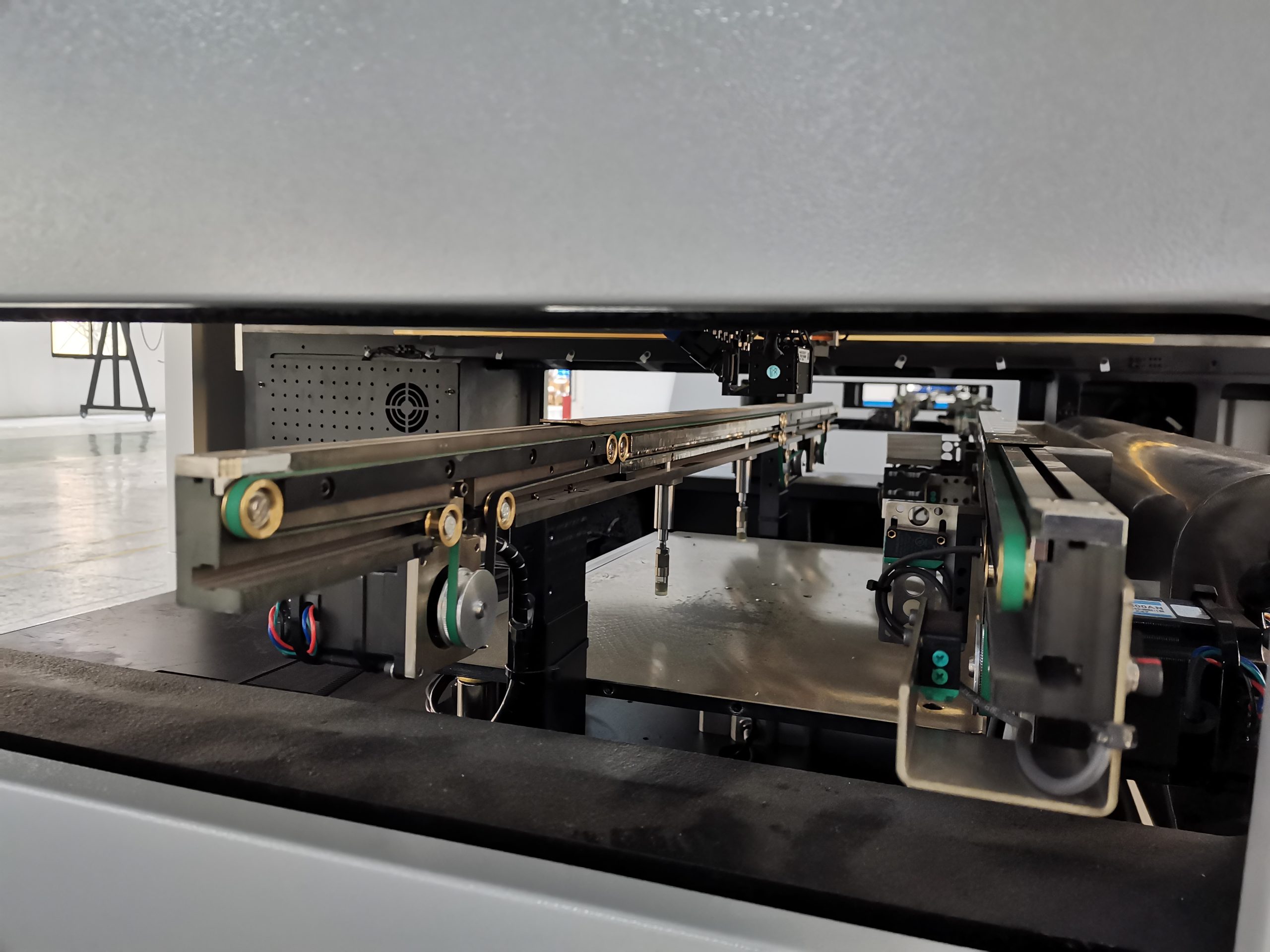

The X,Y,Z Axis drive way adopts the magnetic linear motor and servo motor, which can ensure the high accuracy and precision of mounting;

The feeding way is Electric feeder with double motor;

Single module and 1 mounting head, total has 10 heads, each head is independently controlled by one servo motor;

The X,Y,Z Axis drive way adopts the magnetic linear motor and servo motor, which can ensure the high accuracy and precision of mounting;

The feeding way is Electric feeder with double motor;

The X,Y,Z Axis drive way adopts the magnetic linear motor and servo motor, which can ensure the high accuracy and precision of mounting;

The feeding way is Electric feeder with double motor;

|

Dimension |

2550*1650*1550mm |

|

PCB length width |

Max:1200*500mm Min:100*100mm |

|

No.of feeders station |

28 PCS single module |

|

No.of head |

12 PCS single module |

Magnetic linear motor is adopted to make the production fast, efficient and accurate

Drag chain imported form Germany, IGUS brand

With camera system, automatic identification and mark correction to ensure accurate and efficient mounting

The machine software is independently developed by ETON

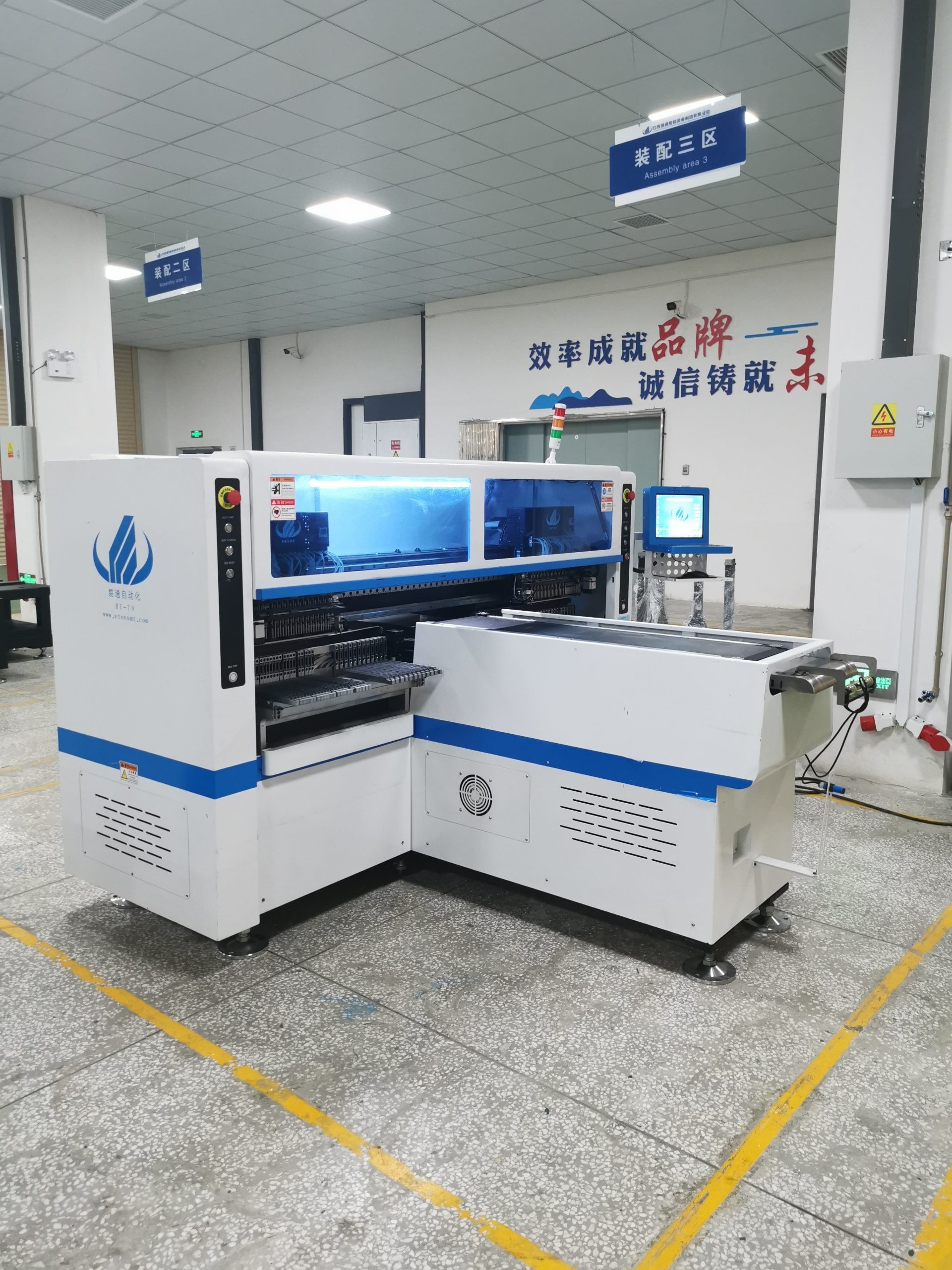

RT-1 can mounted all kinds of components,from 17 mm to 0402

RT-1 has 2 sets of camera to achieve flight identification and Mark correction

RT-1 can achieve group to pick and separate to place, separate to pick and separate to place.

1.Magnetic linear motor and servo motor professional high speed pick and place machine, produce 2 - 4 different types of materials at the same time.

2. 34 PCS of heads, 68 PCS of feeders station, two mounting heads, each mounting head has 17 nozzles, Every mounting head can be mounted separately or synchronously.

3. HT- F7S has the function of calibration automatically and high precision. It is also available for RGB.

1.Magnetic linear motor and servo motor professional high speed pick and place machine, produce 2 - 4 different types of materials at the same time.

2. 34 PCS of heads, 68 PCS of feeders station, two mounting heads, each mounting head has 17 nozzles, Every mounting head can be mounted separately or synchronously.

3. HT- F7S has the function of calibration automatically and high precision. It is also available for RGB.

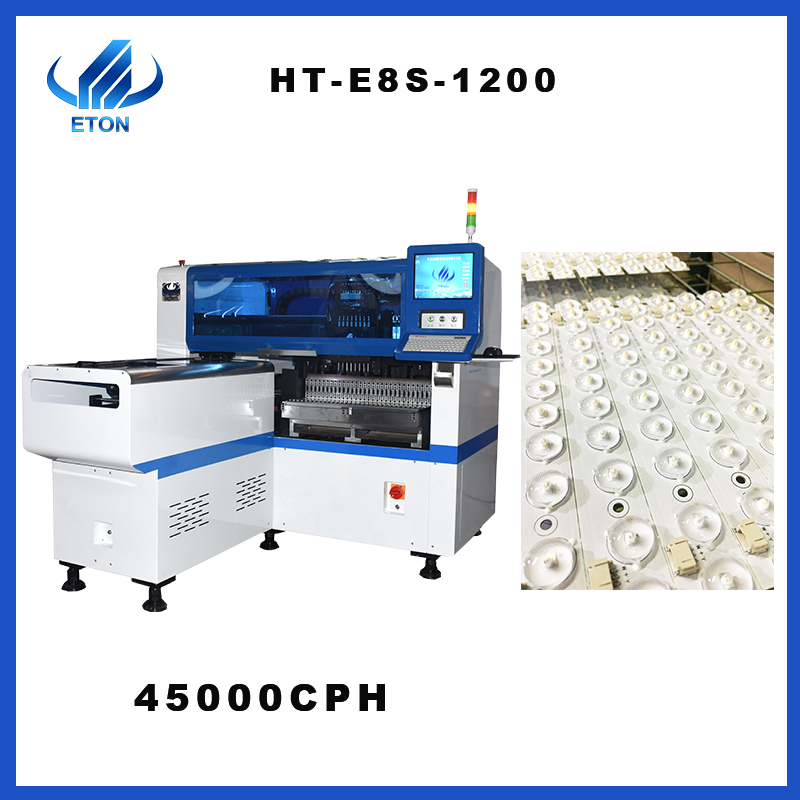

1. suitable for a variety of products: LED bulbs, street light, table light, down lights, power driver, electric board, lens,display screens and linear products, such as LED tube, flexible strip

2. the range of components: led chips, resistor, capacitor, IC, lens, shaped components etc.

3. 12 PCS of heads, 28 PCS of feeders station, mounting speeds up to 45000 CPH.

4. electronic feeder feeding system, vision alignment flight identification, mark correction, non-stop material re-loading function,auto-optimization after coordinates generated.